Linear Multihead Weigher by Kenwei

Product details of the linear multihead weigher

Product Specification

Material: 304 stainless steel

Product Description

Our linear multihead weigher are designed by our professional team. The product complies with international quality standards. This product can be used effectively for various application purposes.

- 01High-precision, high-standard Resolution special load cell.

- 02Module electric board, and with intelligent multiple sampling.

- 03Intelligent fault alarm, convenience for maintenance.

- 04High speed staggered discharging function, effectively prevent blocking materials.

- 05New highly integrated modular design, using CAN bus technology.

- 06Modbus industrial standard communication protocol realizes the multihead weigher and packaging machine interface.

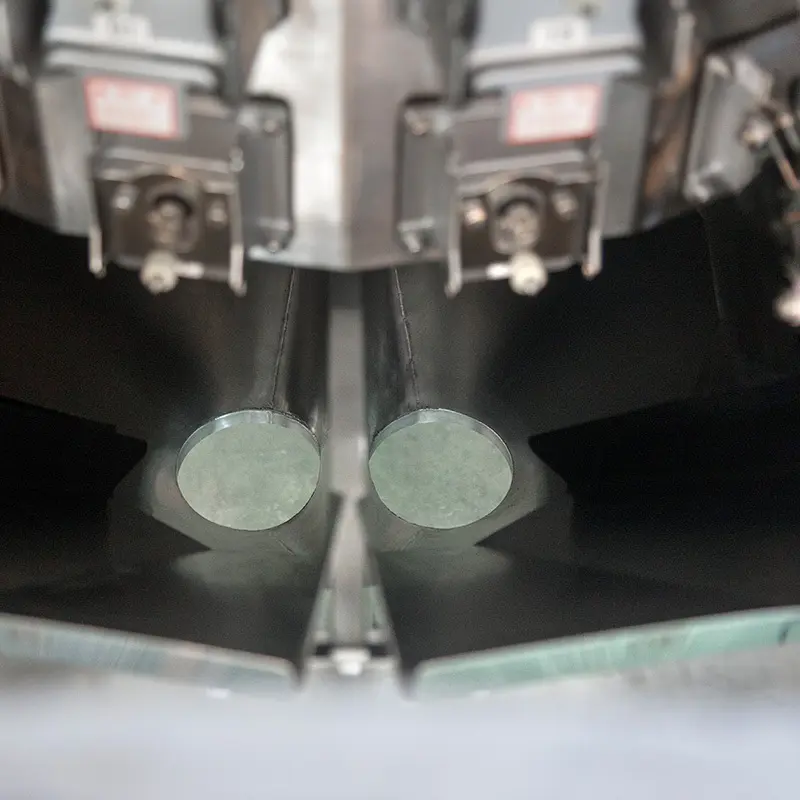

The use of a Ling-shaped hopper makes the material more concentrated and the blanking is faster.

Separate the main vibration plate, the single machine can be used for 2 or 3 kinds of mixed materials formula application.

The chassis and middle seat integrated welding greatly enhance the strength of the machine, making the hopper stable time shorter.

The new memory bucket to make weighing material storage, increase the combined probability and effectively improve the accuracy.

| Model | JW-A18 | |

| Identify Code | A18-4-1 | A18-4-2 |

| Weighing Range | 20~300g | 50~400g |

| Accuracy #1 | X(0.5) | X(0.5) |

| Max. Speed #2 | 180P/M | 180P/M |

| Hopper Volume | 1L | 2.5L |

| Control Panel | 10.1"Touch Screen | |

| Options | Dimple Plate/ Timing Hopper/ Printer/ Reject Device | |

| Driving System | Step Motor | |

| Power Requirement | 220V/2800W/50/60Hz/12.7A | |

| Packing Dimension(mm) | 1190(L)X970(W)X950(H) | 2100(L)X1320(W)X1470(H) |

| Gross Weight | 780kg | 820kg |

| #1: Please refer to national standard GB/T27738-2011 or international recommendation OIML R61 2004 (E) of international Legal Metrological Organization 61. | ||

| #2: Depends on product shape, product density, target weight, etc. | ||

Suitable for all kinds of granular, flake, round, irregular and puffed materials, hardware and other materials, such as melon seeds, peanuts, nuts, almonds, raisins, candies, pistachios, potato chips, meatballs, etc. High-precision quantitative weighing of good materials.

Company Feature

• Kenwei's R&D team has rich experience and mature technology. We have always focused on product innovation and have made a major breakthrough. This lays a solid foundation for the sustainable development of our company.

• Kenwei can provide professional and practical services based on customer demand.

• Founded in Kenwei has a development history of years. Now we become an experienced manufacturer in the machinery industry.

We have strong strength and rich experience. And we are looking forward to discussing business cooperation with partners from all walks of life!

Contact Person: Miss Leung

Phone: +86-0760-22629231 / 22629215 / 22773075

E-Mail:kenwei@multiweigh.com.cn

WhatsApp: +86 18933374210

Add: No.34 Zhenlian Road, Fusha Town, Zhongshan City, Guangdong, China