For Fresh Food & Fruit Snack Food Packaging Machine JW-B2 by Kenwei

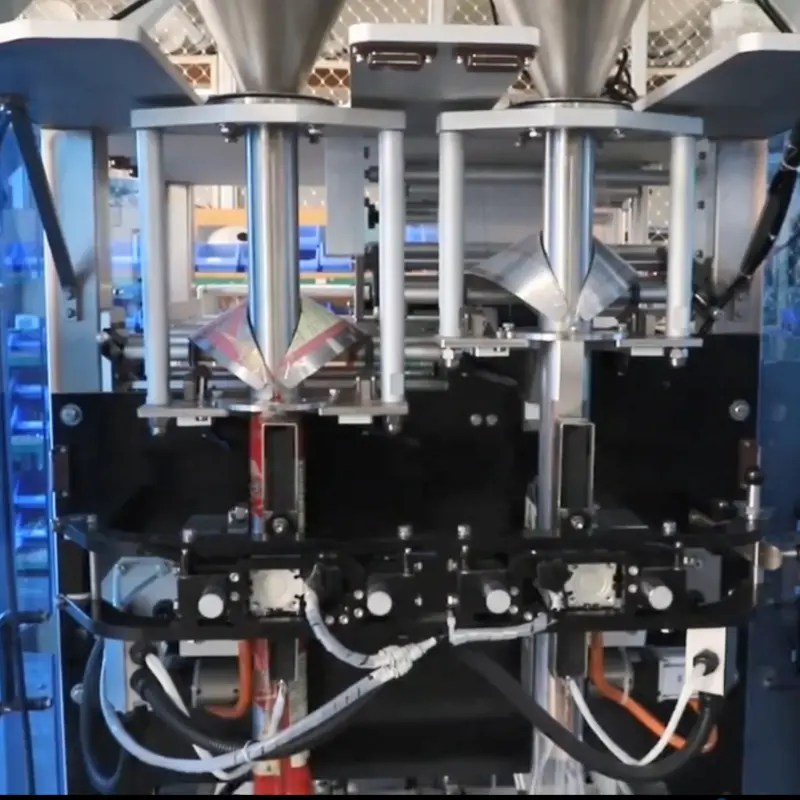

Twin Vertical Packaging Machines with Multihead Weigher for Automated High-Speed Packaging

Twin vertical packaging machines combined with a multihead weigher system are designed for automated high-speed packaging processes in industries such as food, pharmaceuticals, and consumer goods. These machines are engineered to enhance efficiency and precision by simultaneously packaging multiple products or product variations.Applicable to customers who require high production capacity and high production efficiency.

Product Components

System including:Vibrator feeder, Z bucket conveyor, Working platform,14 / 16 head multihead weigher,discharge tube, twin vertical packaging machine.

Customer Case

Twin Vertical Packaging Machine with Multihead Weigher is a powerful combination of two key pieces of automated equipment used in high-speed packaging lines, especially in the food, pharmaceutical, and manufacturing industries. This system integrates the capabilities of twin vertical form-fill-seal (VFFS) packaging machines with multihead weighers, providing an efficient, precise, and flexible solution for packaging a variety of products.

16 Heads high speed multihead weigher

- The double-layer discharge chute, equipped with two high-speed timing hoppers, alternately supplies materials to the packaging machines. This innovative design effectively overcomes the time - consuming issue associated with traditional discharge chute feeding, significantly enhancing the overall feeding efficiency.

- The machine body features an arc - shaped structure, and through meticulous large O treatment, it not only greatly improves the machine's operational stability but also presents an aesthetically pleasing appearance, combining functionality with visual appeal.

- The stable actuator design plays a crucial role in minimizing mechanical vibrations. By reducing vibrations, it ensures that the load cell measurements are more accurate, which is essential for maintaining the precision of the entire packaging process.

Twin Vertical Packing Machines

The film drawing down system and vertical sealing functions are precisely controlled by servo motors. This advanced control method significantly reduces material loss during the production process. Additionally, the system is equipped with a comprehensive automatic warning and protection function. It can promptly detect potential issues and trigger alerts, safeguarding the machine and the production line, and minimizing downtime.

When integrated with feeding and measuring equipment, this machine is a highly versatile all - in - one solution. It can automatically complete a series of operations, including feeding materials, accurate measurement, filling, sealing, date printing,counting, and delivering finished products. This fully automated process streamlines production, improves productivity.

Product

Application

It s ideally suited for accurately measuring granular, (sliced), rolled, or irregularly shaped products. It is widely applicable in various industries, including but not limited to:

- Food sector: Candy, seeds, jelly, fries, coffee granules, peanuts, puffed snacks, biscuits, chocolate, nuts, pet food, frozen feeds, etc.

- Industrial sector: Small hardware components and plastic parts.

Faqs

Twin Vertical Packaging Machine with Multihead Weigher is a powerful combination of two key pieces of automated equipment used in high-speed packaging lines, especially in the food, pharmaceutical, and manufacturing industries. This system integrates the capabilities of vertical form-fill-seal (VFFS) packaging machines with multihead weighers, providing an efficient, precise, and flexible solution for packaging a variety of products.

Company Advantages

· The materials of Kenwei snack food packaging machine meet the international quality standards.

· The product has been approved by the ISO9001 Certification.

· Guangdong Kenwei Intellectualized Machinery Co.,LTD.'s snack food packaging machine has been well sold to all over the world known as its diversification, good customer service and excellent quality.

Company Features

· With the integration of industry and trade, Guangdong Kenwei Intellectualized Machinery Co.,LTD. is a professional snack food packaging machine manufacturer in China. So far, the company has accumulated abundant experience in this field.

· Guangdong Kenwei Intellectualized Machinery Co.,LTD. has strong R&D capability and superior process technologies for snack food packaging machine.

· Our corporate culture is to be innovative. That is, to work outside the box, to reject mediocrity, and to never drift along.

Application of the Product

Kenwei's snack food packaging machine is widely used in various scenes.

Kenwei is dedicated to solving your problems and providing you with one-stop and comprehensive solutions.