Kenwei simple wrapping machine trade partner

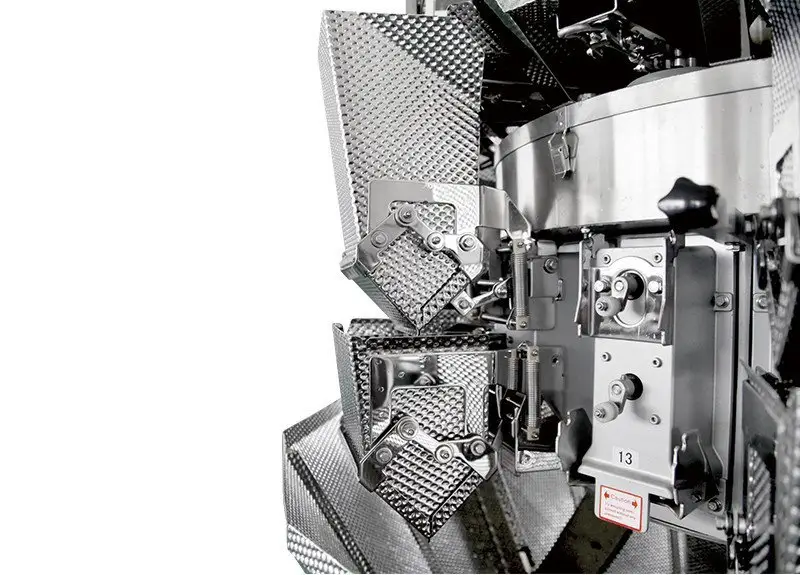

1. In the manufacture of Kenwei wafer packaging machine , it has to go through a series of production processes, including metal materials CNC cutting, milling, welding, and assembly. Kenwei packaging machine works at high speed

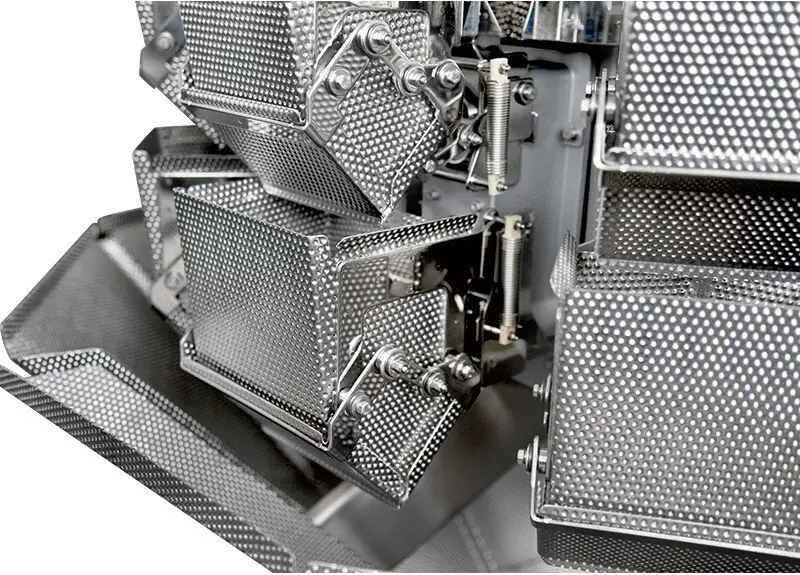

2. Works can get rid of jobs that are dirty dull. They will take more interest in their work and their efficiency will increase. Kenwei packaging machine is easy to clean

3. The product is stable in performance and long in service life. Kenwei packaging machine is cost-effective and quality-high

4. With superior craftsmanship, Kenwei ensures the quality of this product. Kenwei packaging machine is certified under CE

5. Through a rigorous quality control system, the stability of this product is ensured. Operation of Kenwei packaging machine is safe and reliable

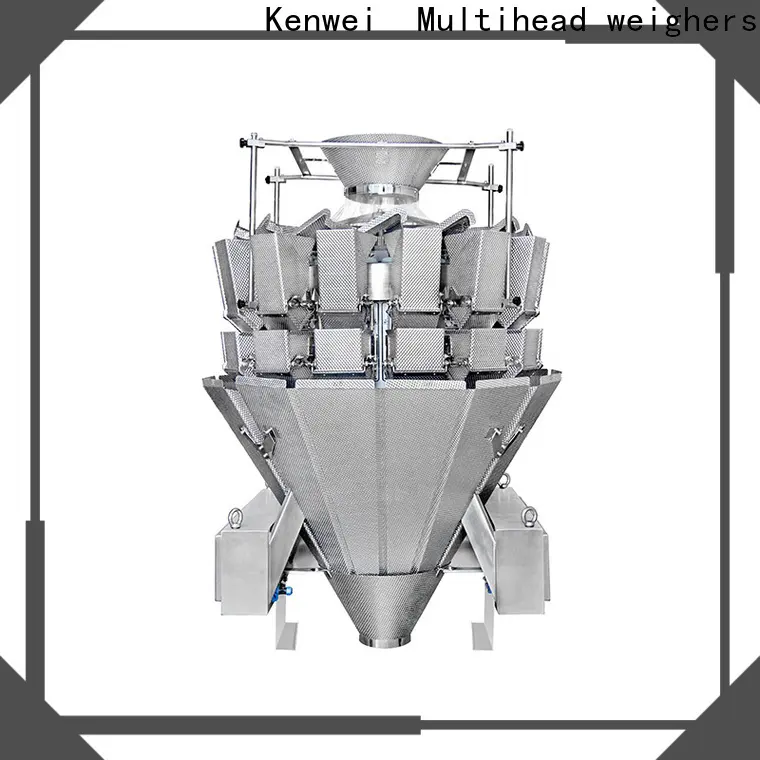

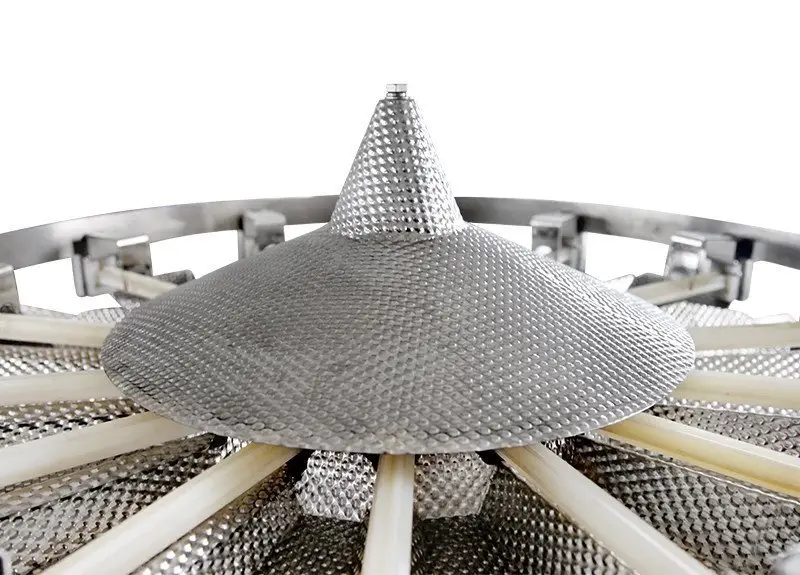

Noodle combination weigher uses pattern board material to avoid material sticking hopper. It is suitable for weighing soft long strip materials such as soft noodles and noodles. Noodle scales are equipped with drying dewatering devices and waterproof chassis of IP65 grade, which effectively prevents the damage of electrical components in the chassis. As a manufacturer of combination weigher, we have our own combination weigher factory.

Product Features

Product Characteristic

2.IP65 cabinet design, dimple plates for food contact parts;

4.60° steep discharge chute makes sure products discharge smoothly;

6.Rotary rollers equipped between each linear feeder pan helps to dispense the long soft products into feed hoppers.

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-6 | A14-1-6 |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 30P/M | 60P/M |

Hopper Volume | 2.5L | |

Control Panel | 7” Touch Screen | |

Options | Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 200V/1000W/50/60/Hz/10A | 220V/1500W/ 50/60Hz /12A |

Packing Dimension(mm) | 1620(L)X1100(W)X1420(H) | 1750(L)X1160(W)X1420(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing soft strip products such as noodles, rice noodles, bean sprout, etc

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is called as an expert in the industry. We are competent in the design and production of wrapping machine .

2. As society developed, Kenwei has been stressing the importance of a high-quality bottle filling machine .

3. We think highly of service-orientation. We attach importance to long-term business cooperations with clients and we'll spare no efforts to offer them professional guidance and advice.