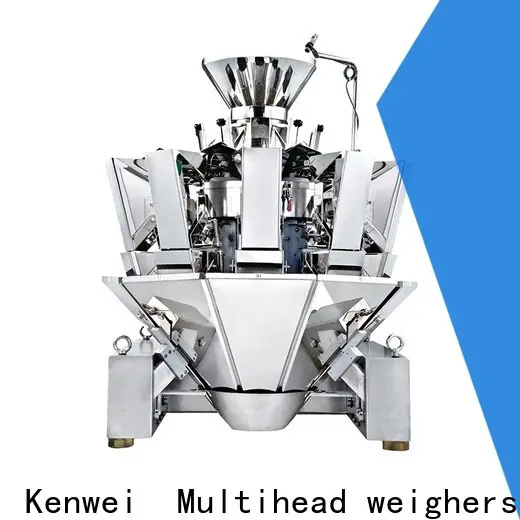

Kenwei simple bottle filling machine factory

1. The design of Kenwei bottle filling machine shows professionalism. The mechanical properties, including materials hardness, structural toughness, efficiency, fatigue resistance have all optimized. Component replacement of each Kenwei packaging machine is simple and without trouble

2. With promising development prospects in the field, the product is widely used. It is easy and convenient to operate Kenwei packaging machine

3. The product has a smooth surface. It is furnished with a layer of glaze that can reduce the surface roughness. Kenwei packaging machine is manufactured based on industry standards

4. The product features safety during operation. The electrical system and its relevant accessories all meet the requirements of IEC general standards. Kenwei packaging machine is certified under CE

5. The product can be used for a long time. It is sturdy in construction, which means that its frame can be resistant to impacts and protects internal circuits from shocks. Kenwei packaging machine works at high speed

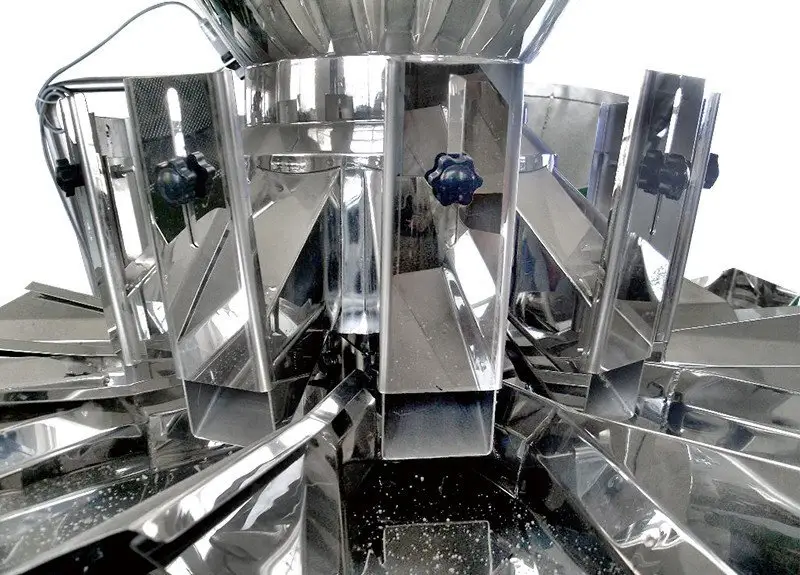

The leak proof multi head weigher adopts a special deep U-shaped vibrating plate to avoid material leaking to both sides of the vibrating plate when weighing. It is suitable for the quantitative weighing of various micro-particles such as rice, chicken essence, monosodium glutamate and other materials. The newly added multi-angle hopper effectively distributes materials to the vibrating plates of various lines, reduces production costs and improves economic benefits.

Product Features

Product Characteristic

2.Specially designed U-shaped linear feeder pans can avoid leaking problems.

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-4 | A14-1-4 |

Weighing Range | 20-1000g | 20-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6L/2.5L | |

Control Panel | 7” Touch Screen | |

Options | Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /12A |

Packing Dimension(mm) | 1620(L)X1100(W)X1110(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing small granules such as rice, sugar, fine tea, detergent powder, etc

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is a professional manufacturer in the field of bottle filling machine .

2. Thanks to the solid technical foundation, Guangdong Kenwei Intellectualized Machinery Co.,LTD. stands out in the weigher industry.

3. The solid implementation of scientific principles of meat weigher ensure Guangdong Kenwei Intellectualized Machinery Co.,LTD. lead the world in the development trend of multi head packing machine. Please contact us!