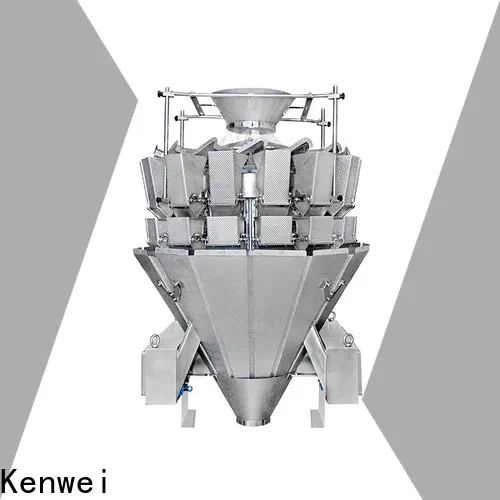

Kenwei long-life multihead weigher affordable solutions

1. combination scale makes multihead weigher very competitive in the market. Kenwei packaging machine is easy to clean

2. The product, providing a great probability for users, has an extensive application in the global market. Kenwei packaging machine records less than 0.5% failure rate within 1 year

3. The product is notable for high energy efficiency. When it operates, it can utilize little energy as possible without any waste. Quality control from material to finished product is taken strictly over Kenwei packaging machine

4. It features a long mechanical life. It has been tested by exposure to EMC, high and low temperatures, moisture, dust, mechanical shock, vibration, sunlight, salt mist, and other corrosive environments. Maintenance is easy in Kenwei packaging machine

5. The product features strong compatibility. It doesn't just work alone. Other function can be added to work with this machine system. Kenwei packaging machine helps save costs and improve production efficiency

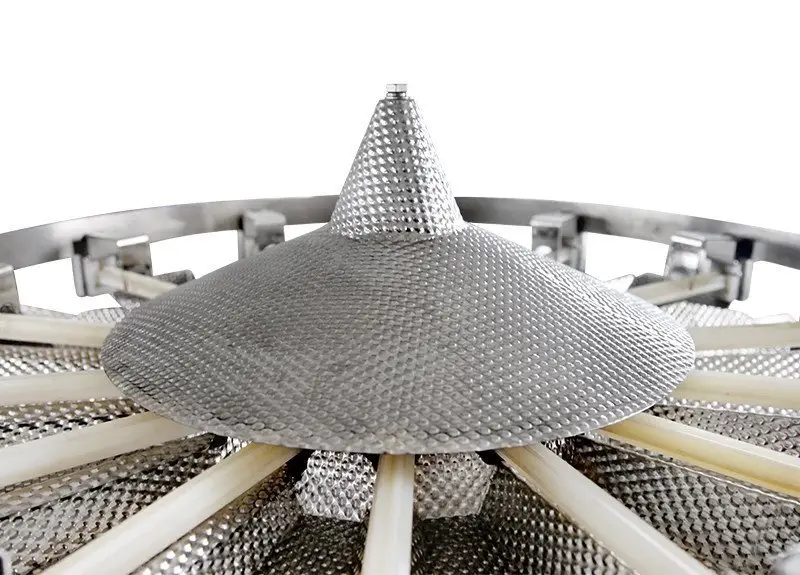

Noodle combination weigher uses pattern board material to avoid material sticking hopper. It is suitable for weighing soft long strip materials such as soft noodles and noodles. Noodle scales are equipped with drying dewatering devices and waterproof chassis of IP65 grade, which effectively prevents the damage of electrical components in the chassis. As a manufacturer of combination weigher, we have our own combination weigher factory.

Product Features

Product Characteristic

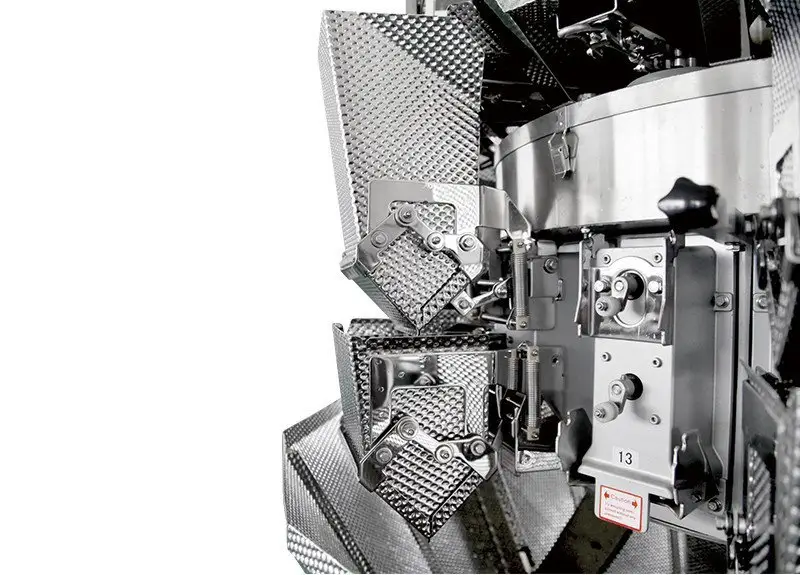

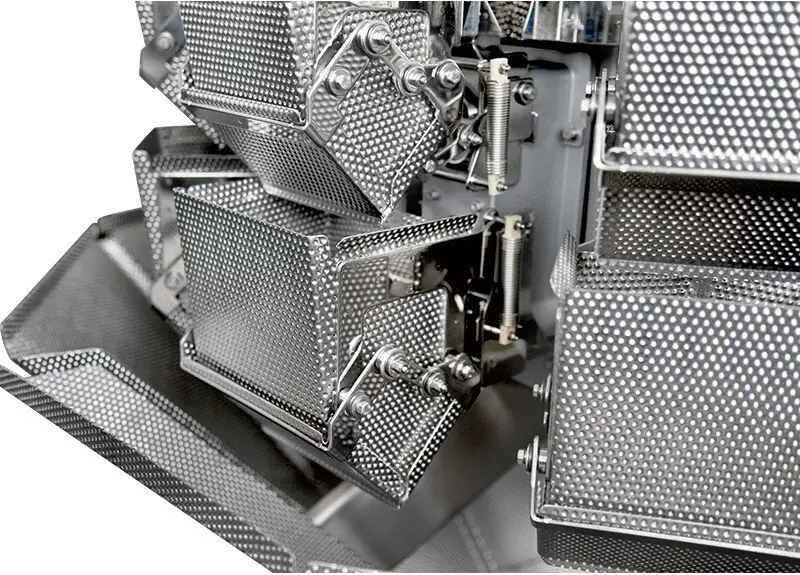

2.IP65 cabinet design, dimple plates for food contact parts;

4.60° steep discharge chute makes sure products discharge smoothly;

6.Rotary rollers equipped between each linear feeder pan helps to dispense the long soft products into feed hoppers.

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-6 | A14-1-6 |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 30P/M | 60P/M |

Hopper Volume | 2.5L | |

Control Panel | 7” Touch Screen | |

Options | Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 200V/1000W/50/60/Hz/10A | 220V/1500W/ 50/60Hz /12A |

Packing Dimension(mm) | 1620(L)X1100(W)X1420(H) | 1750(L)X1160(W)X1420(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing soft strip products such as noodles, rice noodles, bean sprout, etc

Company Features

1. There is a dedicated team in Guangdong Kenwei Intellectualized Machinery Co.,LTD. that researches and tests new multihead weigher products.

2. Our company is based on values. These values include working hard, building relationships and providing quality service to clients. These values ensure that the manufactured product portrays the image of the client company. Please contact us!