Company Advantages1. Kenwei pouch packing machine is manufactured with a series of mechanical components. They are a machine base, column, worktable, spindle cases, carriages, and so on. Kenwei packaging machine works at high speed

2. The product is suitable for various applications and is now widely used in the market. Kenwei packaging machine records less than 0.5% failure rate within 1 year

3. Adopting such design, pouch packing machine is provided with many merits like combination scale and so on. Kenwei packaging machine helps save costs and improve production efficiency

4. pouch packing machine is the best combination scale with peculiarities like automatic weighing and filling machine . Kenwei packaging machine is easy to clean

1、The whole machine is made of stainless steel food-grade materials to ensure food hygiene and safety.

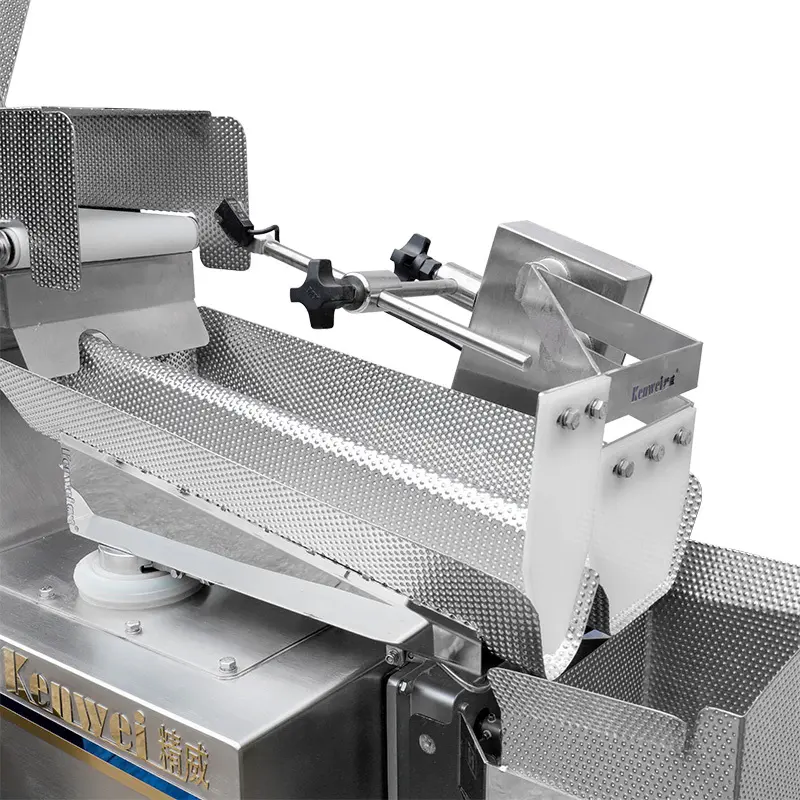

2、Customized food-grade conveyor belt to meet different application requirements of different materials.

3、Easy to disassemble structure design, easy to maintain and clean.

4、Customize special sensors to ensure weighing accuracy.

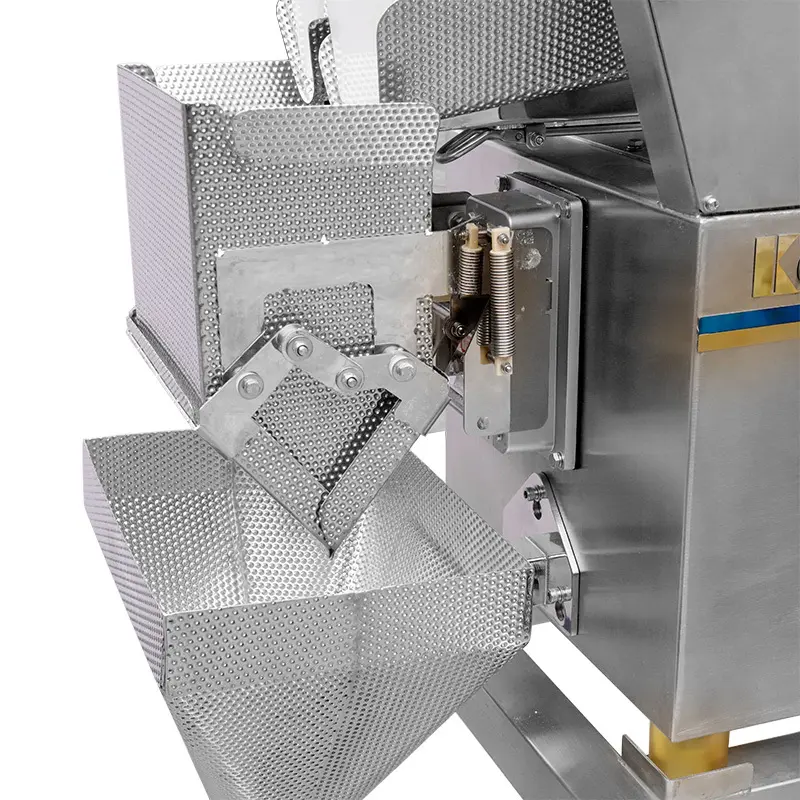

5、Double-vibration plate is used for blanking, the main vibration plate is quickly fed, and the auxiliary vibration plate is accurately refilled to ensure feeding accuracy.

6、The main and auxiliary vibration plates are equipped with independent gates, which automatically realize the opening and closing actions of the gates according to the signal feedback.

7、Parts in contact with materials can be quickly disassembled, making cleaning more convenient.

8、The front inclined upper hopper mechanism has a good anti-bridging effect on viscous materials.

![product-Kenwei -img]()

Brand new highly integrated modular control system.

![product-Kenwei -img]()

During operation, the parameter settings can be modified according to the actual production conditions, and the operation is simple.

![product-Kenwei -img]()

Adopting double-layer feeding structure, upper belt feeding, lower vibrating plate feeding, it is convenient to control the thickness of the line vibrating plate material to ensure accurate feeding.

![product-Two Layers Belt Vibrate Linear Weigher Machine-Kenwei -img]()

The stepless feeding mode is adopted to control the flow of materials in real time to ensure the accuracy of weighing.

TECHNICAL SPECIFICATION

bg

| Model | JW-AX1 |

| Identify Code | X1-2-10 |

| Weighing Range | 50~1000g |

| Accuracy #1 | X(1) |

| Max. Speed #2 | 10P/M |

| Hopper Volume | 4.5L |

| Parameters Press No. | 100 |

| Max Products Mixed | 1 |

| Control Panel | 7” Touch Screen |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device |

| Power Requirement | 220V / 1200W / 50/60Hz / 6A |

| Packing Dimension(mm) | 1200(L)x660(W)x1050(H) |

| Gross Weight | 110kg |

| #1: Please refer to national standard GB/T27738-2011 or international recommendation OIML R61 2004 (E) of international Legal Metrological Organization 61. |

| #2: Depends on product shape, product density, target weight, etc. |

It is suitable for quantitative weighing of brown sugar, brown sugar, industrial salt, etc., which have poor fluidity and slight viscosity, as well as fresh corn kernels, cauliflower, onion slices and other block, diced, stems, and other vegetables and medicinal products.

Guangdong Kenwei Intellectualized Machinery Co.,LTD., a Chinese

pouch packing machine manufacturer, has professional and abundant experience in developing, manufacturing, and supplying in the industry. Guangdong Kenwei Intellectualized Machinery Co.,LTD. produces with a scientific management model.

2. Kenwei has excellent technology to be applied in the production of packaging machine .

3. Kenwei strongly emphasizes the importance of applying high technology. Our company will actively foster sustainable practices. We will conduct production in an environmentally and socially responsible manner, such as reducing waste gases, polluted water, and conserving resources.