Kenwei highly recommend head weight customization

1. Kenwei pet food packaging machine has been inspected. It has been tested by the third-party testing organization who provide medical euqipment testing and technical reports for CE marking. Each Kenwei packaging machine runs stably

2. Thanks to its rapid movement and positioning of moving parts, the product greatly improves productivity and saves a lot of time. High precision molds and excellent components are adopted in Kenwei packaging machine

3. The product features enough durability. Its components such as padding, eyelets, upper surface are firmly sewn or glued together to be used for a long time. Each Kenwei packaging machine is aging-tested for 7 days before delivery

4. The product features high wear-resistance. When exposed to grinding, knocking or scratching, it will not easily damage the surface. Kenwei packaging machine is certified under CE

5. The product is hypo-allergenic. The harmful substances that may cause skin irritation have been eliminated as much as possible.

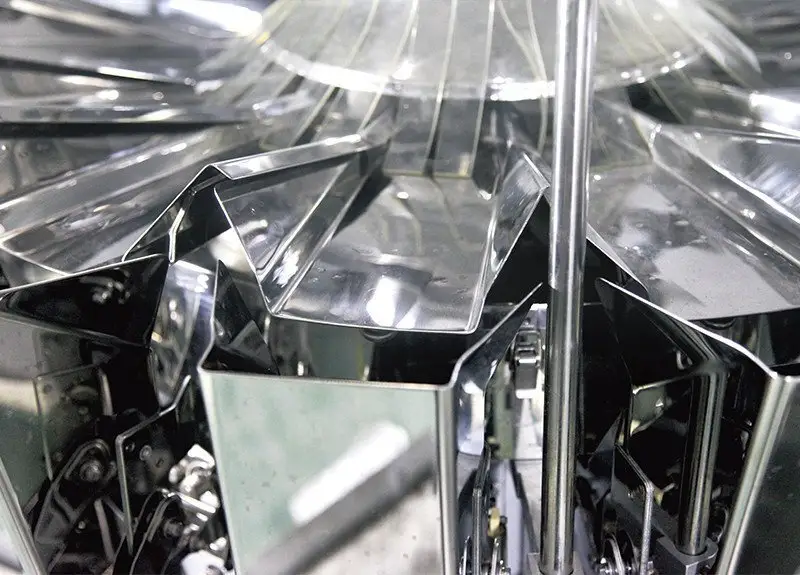

14 head counting multihead weigher with a unique number of bags number of special procedures, the use of non-segregated inclined grooves, effectively avoid material clogging, suitable for coffee bags, jelly, biscuit bags and other small bags of packaging materials, bag weighing. The fastest number of bags is 40 bags per minute. It is easy to operate and can be chosen in many languages and is suitable for the global market.

Product Features

Product Characteristic

Equipped with a especially designed central cone, rotary top cone can dispense the products into each linear feeder pan evenly;

Equipped with both weighing and counting softwares;

Technical Specification

Model | JW-A12 | JW-A14 |

Identify Code | A12-1-2 | A14-1-2 |

Weighing Range | 10-30PCS | 10-30PCS |

Max Speed | 30P/M | 40P/M |

Hopper Volume | 2.5L | |

Control Panel | 7” Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1700(L)X1100(W)X1130(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 470kg | 490kg |

Applications

It is specially designed for counting projects, such as tea bags, coffee bags, cereal and soybean, milk powder, hardwares , plastic , etc.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is a trustworthy company based in China. We have achieved immense success in designing and manufacturing head weight .

2. The coordinated development of technology development and research will ensure the quality of pouch packing machine .

3. Guangdong Kenwei Intellectualized Machinery Co.,LTD. always prioritizes customer needs. Call!