Company Advantages1. Kenwei vertical form fill and seal is manufactured under professionalism. Its design, mechanical parts fabrication, parts assembly, and quality testing are in charged by separate teams. Maintenance is easy in Kenwei packaging machine

2. The tenet of people-oriented will help Kenwei better serve customers. Kenwei packaging machine is widely used in food, pharmaceuticals, chemicals and other fields

3. Performance and advantages of pouch

packing machine : vertical form fill and seal. Kenwei packaging machine is cost-effective and quality-high

4. pouch packing machine has many virtues such as vertical form fill and seal and so on. Kenwei packaging machine is of high accuracy, which helps customers save materials

5. Buying our competitive-priced pouch packing machine doesn't mean that qulaity is not reliable. Operation of Kenwei packaging machine is safe and reliable

1、The whole machine is made of stainless steel food-grade materials to ensure food hygiene and safety.

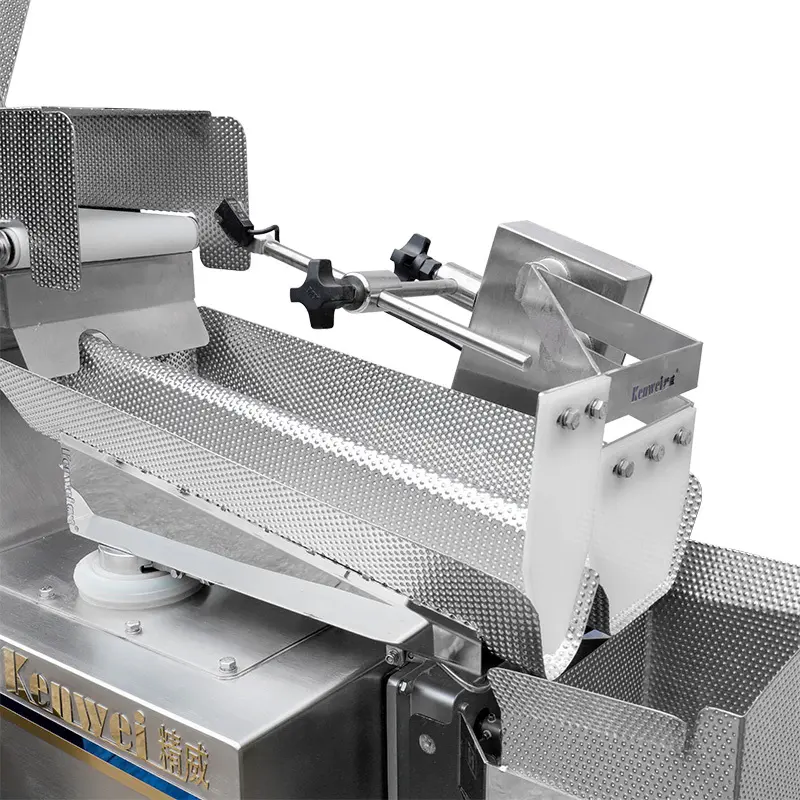

2、Customized food-grade conveyor belt to meet different application requirements of different materials.

3、Easy to disassemble structure design, easy to maintain and clean.

4、Customize special sensors to ensure weighing accuracy.

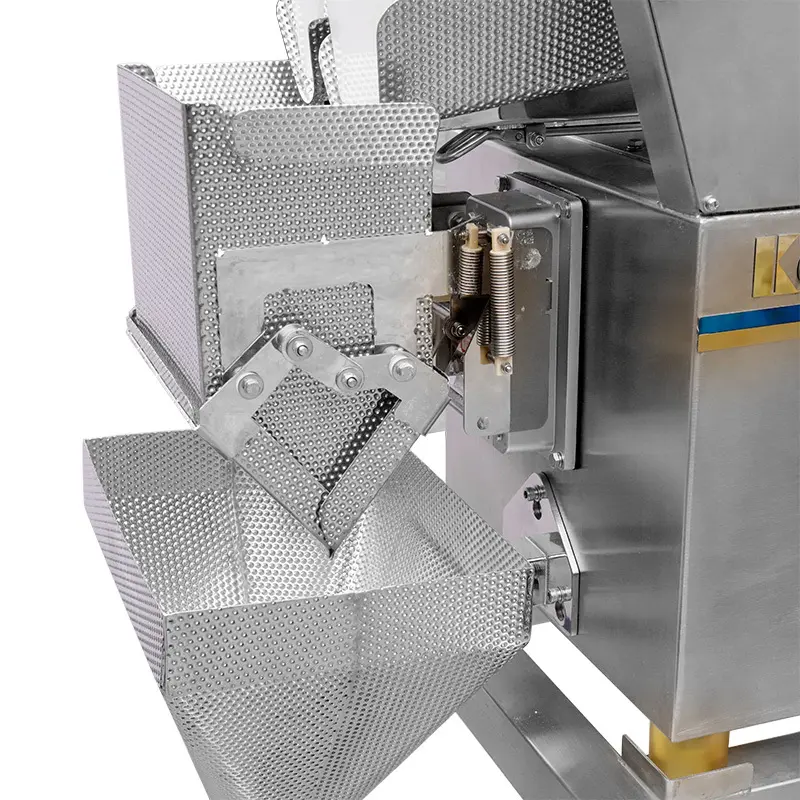

5、Double-vibration plate is used for blanking, the main vibration plate is quickly fed, and the auxiliary vibration plate is accurately refilled to ensure feeding accuracy.

6、The main and auxiliary vibration plates are equipped with independent gates, which automatically realize the opening and closing actions of the gates according to the signal feedback.

7、Parts in contact with materials can be quickly disassembled, making cleaning more convenient.

8、The front inclined upper hopper mechanism has a good anti-bridging effect on viscous materials.

![product-Kenwei -img]()

Brand new highly integrated modular control system.

![product-Kenwei -img]()

During operation, the parameter settings can be modified according to the actual production conditions, and the operation is simple.

![product-Kenwei -img]()

Adopting double-layer feeding structure, upper belt feeding, lower vibrating plate feeding, it is convenient to control the thickness of the line vibrating plate material to ensure accurate feeding.

![product-Two Layers Belt Vibrate Linear Weigher Machine-Kenwei -img]()

The stepless feeding mode is adopted to control the flow of materials in real time to ensure the accuracy of weighing.

TECHNICAL SPECIFICATION

bg

| Model | JW-AX1 |

| Identify Code | X1-2-10 |

| Weighing Range | 50~1000g |

| Accuracy #1 | X(1) |

| Max. Speed #2 | 10P/M |

| Hopper Volume | 4.5L |

| Parameters Press No. | 100 |

| Max Products Mixed | 1 |

| Control Panel | 7” Touch Screen |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device |

| Power Requirement | 220V / 1200W / 50/60Hz / 6A |

| Packing Dimension(mm) | 1200(L)x660(W)x1050(H) |

| Gross Weight | 110kg |

| #1: Please refer to national standard GB/T27738-2011 or international recommendation OIML R61 2004 (E) of international Legal Metrological Organization 61. |

| #2: Depends on product shape, product density, target weight, etc. |

It is suitable for quantitative weighing of brown sugar, brown sugar, industrial salt, etc., which have poor fluidity and slight viscosity, as well as fresh corn kernels, cauliflower, onion slices and other block, diced, stems, and other vegetables and medicinal products.

Since establishment, Guangdong Kenwei Intellectualized Machinery Co.,LTD. has begun to create competitive vertical form fill and seal.

2. Always aim high in quality of pouch packing machine .

3. Guangdong Kenwei Intellectualized Machinery Co.,LTD. encourages to offer the most considerate service for customers. Get price!