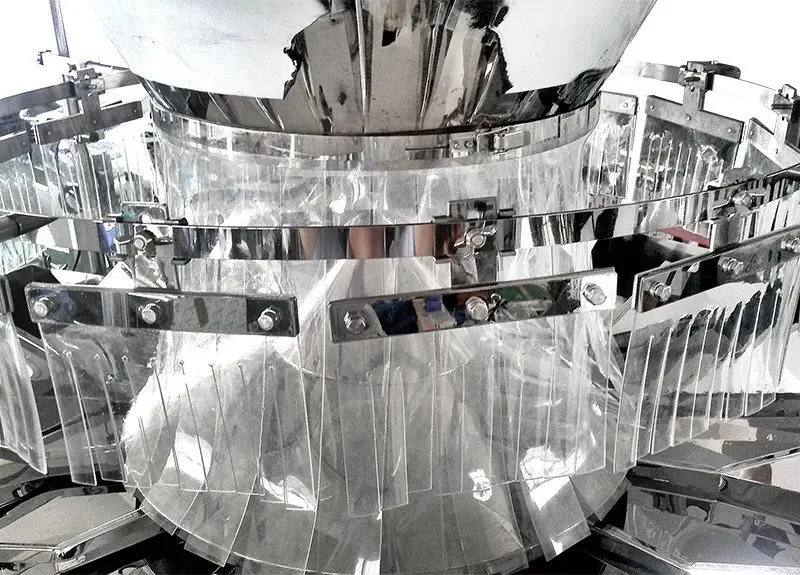

Kenwei heads wrapping machine with high-quality sensors for spicy fish

1. There are many factors being considered while designing Kenwei home made packing machine . They are the selection of materials, modes of loading, safety factors, allowable stresses, etc.

2. The product features easy maintenance. It is designed with certain automatic function that detects malfunction itself, which greatly reduces the machine checking and maintenance times.

3. The product is built to last. It holds the features of rust-resistant to prevent it from water or moisture corrosion on the basis of the high-quality metal materials used in it.

4. By using this product, the chances of errors will be greatly reduced. This will contribute to the reduction in production costs due to human error.

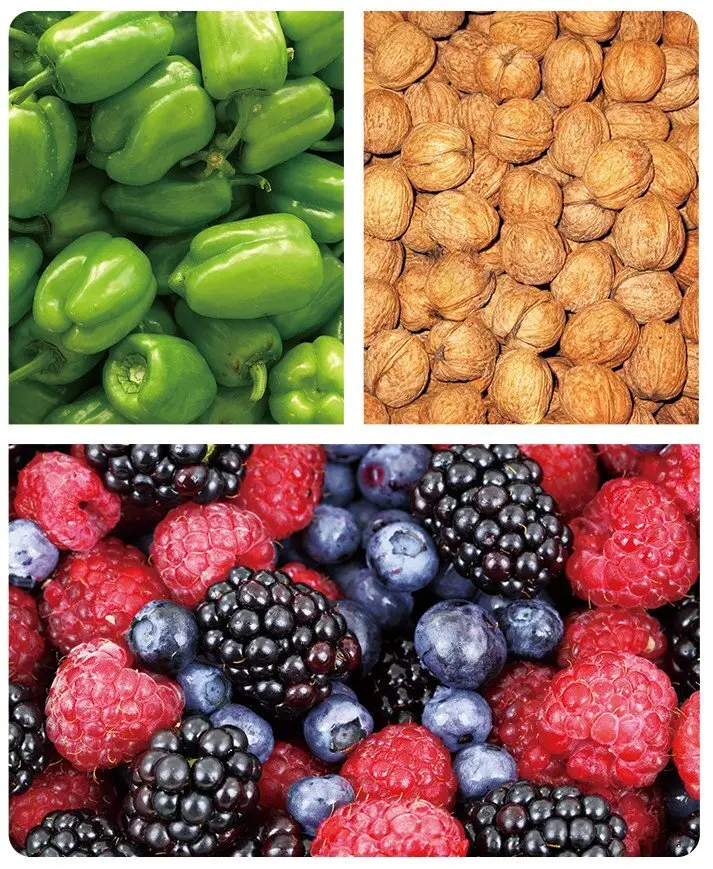

Feeding control multihead weigher is suitable for weighing green pepper, fruit, jelly, and other large bulk materials with less grain count.

The maximum weighing speed of 14 head feeding control multihead weigher is 60 bales/minute, with high weighing accuracy.

product features

product characteristic

2. Vibration time is automatically adjusted to make sure a good feeding process and improve the combination possibility.

4. Wide V shape feeder pan with an independent photo sensor on its top, feeding process can be more uniform.

6. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time.

Technical Specification

Model | JW-A14 | JW-A10 |

Identify Code | A14-1-8 | A14-1-8 |

Weighing Range | 10-1500g | 10-1000g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 60P/M | 30P/M |

Hopper Volume | 1.6L/2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1500W/ 50/60Hz //12A | 220V/1000W/ 50/60Hz //10A |

Packing Dimension(mm) | 1700(L)X1110(W)X1265(H) | 1620(L)X1100(W)X1110(H) |

Gross Weight | 490kg | 380kg |

Applications

It is suitable for counting project, such as pepper, fruit, jelly, small packs, tomato, potato, onion, large-shell nuts, etc.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is proud of its exceptional record of creating a collection of wrapping machine .

2. We have formed the most professional and best management team. They are qualified in providing technical support, product information, scheduling, and materials procurement, which greatly facilities the production and services work.

3. We will do all the best to make Kenwei to be the most famous brand. Welcome to visit our factory! Innovation can be said as a responsibility for Guangdong Kenwei Intellectualized Machinery Co.,LTD.. Welcome to visit our factory! Guangdong Kenwei Intellectualized Machinery Co.,LTD. will strive to become the industry's leading enterprises, promote and lead the industry's development. Welcome to visit our factory!

Model No. : OP2-BK

Material : Electrolytic Galvanized Iron

Surface : Colored Powder Coating

Slot : Large Slot & Small Slot

Umbrellas : Full-size, Half-size or 3 folded Umbrella

Loading : 1,000 PCS Plasticbags x 2

PlasticBags : Model No. OBL (long bags) & OBS (short bags)

Package : Each Unit to the Master Carton

Carton Size : 46cm x 41cm x 85cm (0.16 CBM)

Gross Weight : 19.0 Kgs

Measure Weight : 32.0 Kgs

Semi-automatic Strapping Wrapping Machine Carton Box Packing Machine Factory

Introduction

This machine is with polyethylene plastic bands tied materials, mainly for the commercial, postal, railway, bank, food, medical, publications, publishing industries cartons, wooden box, paper bag, cloth pack into the packing belt, the machine can complete the automatic take-up, sealing, cutting off and out of band. And have the function of automatic stop. High working speed, high efficiency, time and labor saving packing of high quality. There are high and low two luxury models.

Feature

1. The machine adopts the new type of integrated circuit, the access type PC board to control the whole packaging action subwoofer design.

2. The whole machine combination perfect maturity, low noise, reduce the pressure of work.

3. Packing speed, each bale in just 2 seconds; transient heating, 5 seconds can make the heating piece work, into the best state of packing, power utility.

4. 60 seconds to stop at the standby state packing action is completed, a new generation of electric steel sheet design.

5. Improved design, careful manufacture, wide application range, regardless of the size of the packaging, do not adjust the machine can pack.

6.The machine is a mechanical structure, part of the use of imported parts, after the blade is stable and reliable, easy adjustment and etc..

7.The strapping table is high, operation convenience, suitable for packing lighter items.

8. No deformation characteristics of short circuit, and the packaging is applicable range is extensive.

9. Market any packing tape, width is 6 mm to 15 mm, bonding effect is best.

Advantage

The motor + reducer + CAM operation, completely avoid, strapping end, motor immediately stop (energy saving).

Nonskid stop tightening force, tooth structure glue, cutting knives of high strength, good performance, long service life.

The movement and control body shell to the overall beauty of aluminum alloy die-casting molding, never rust.

Components are produced by computer numerical control machine tool precision, mechanical operation table more downy, durability, functional.

Elastic band and reservoir can be self-regulating.

Used especially ultra-thin high quality better! Cost can reduce 30-50%.

Main technical parameters

Model | SP-02 |

Voltage | 220v,50Hz/60Hz,110v,60Hz |

Power | 0.45kw |

PP band width | 6-15mm |

PP core size | 200*200mm |

Max packing size | Unlimited |

Min packing size | 60mm |

Max trap force | 5-60kg/s |

Working speed | 1.2s/pc |

Machine size | 1490*565*460mm |

Machine weight | 80kg |