Kenwei flexibly bottle filling machine with high-quality sensors for materials with oil

1. Kenwei automatic weighing is created in an avant-garde way. Its design performs various manufacturing technologies such as plastic injection, machining, sheet metal and die castings. It is a great variety of Kenwei packaging machines for choices

2. The product is popular among the customers with high cost performance and takes a large market share. Kenwei packaging machine works at high speed

3. We have conducted various stringent tests to make sure the product is defect-free and meets the high quality standard. It is easy and convenient to operate Kenwei packaging machine

4. The advanced test method is conducted to ensure the quality of this product. Kenwei packaging machine is environmental-friendly

5. The product has the stable performance and can be stored in a good condition. Kenwei packaging machine is cost-effective and quality-high

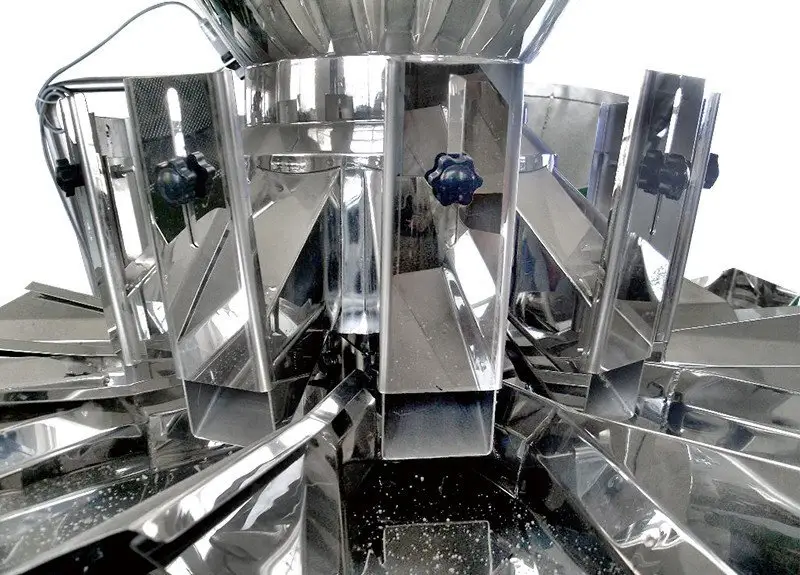

The leak proof multi head weigher adopts a special deep U-shaped vibrating plate to avoid material leaking to both sides of the vibrating plate when weighing. It is suitable for the quantitative weighing of various micro-particles such as rice, chicken essence, monosodium glutamate and other materials. The newly added multi-angle hopper effectively distributes materials to the vibrating plates of various lines, reduces production costs and improves economic benefits.

product features

product characteristic

2.Specially designed U-shaped linear feeder pans can avoid leaking problem.

Technical Specification

Model | JW-A12 | JW-A14 |

Identify Code | A10-1-4 | A14-1-4 |

Weighing Range | 20-1000g | 20-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6L/2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /12A |

Packing Dimension(mm) | 1620(L)X1100(W)X1110(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing small granules such as rice, sugar, fine tea, detergent powder, etc

Company Features

1. Modern production equipment can fully guarantee the quality of bottle filling machine .

2. Always taking the road of sustainable development with automatic weighing and bag filling machine is our pursuing goal. Get more info!