Kenwei feeding weight checker easy to disassemble for materials with oil

-

v s

1. Since salt packaging equipment technological measures were put forward, weight checker 's body frame has been highly improved.

2. The quality and performance of the product are first-class in the industry.

3. This product has a wide reputation in the industry with its considerable features.

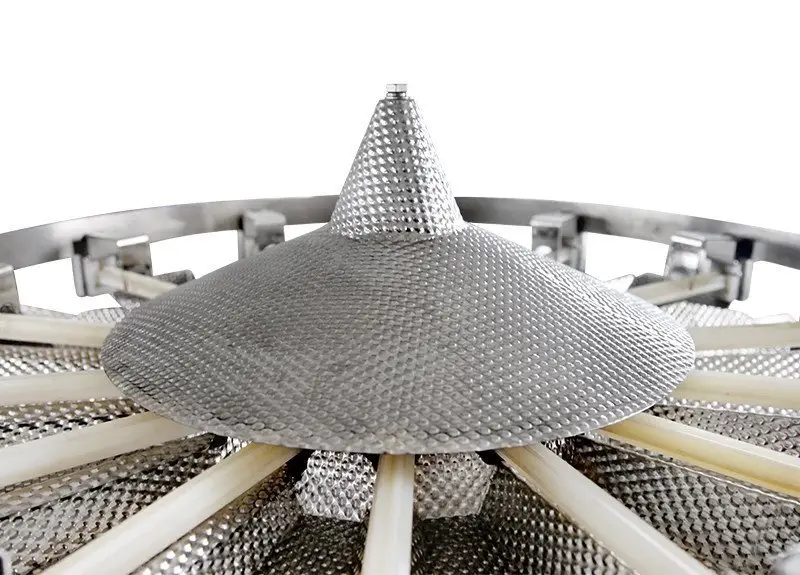

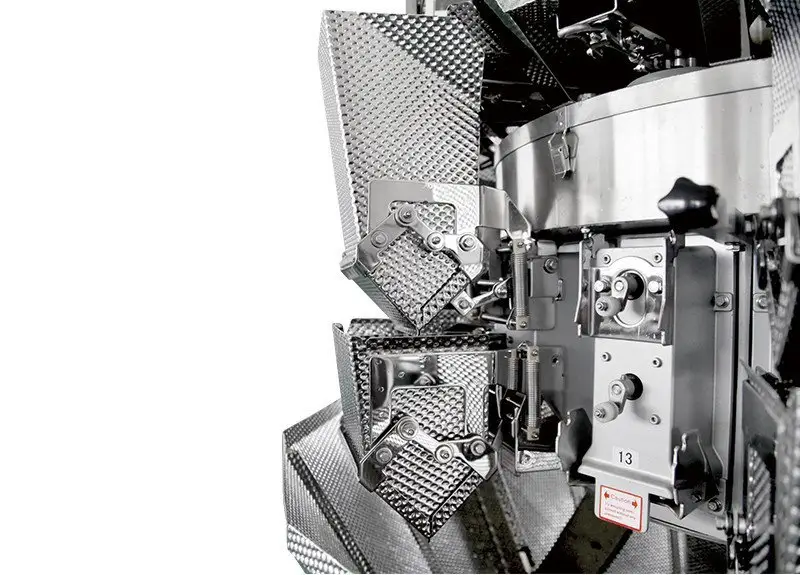

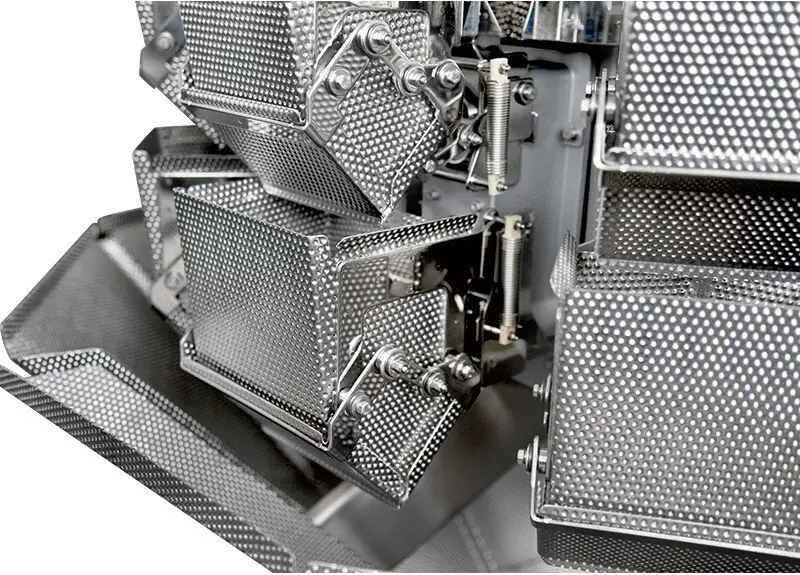

Noodle combination weigher uses pattern board material to avoid material sticking hopper. It is suitable for weighing soft long strip materials such as soft noodles and noodles. Noodle scales are equipped with drying dewatering devices and waterproof chassis of IP65 grade, which effectively prevents the damage of electrical components in chassis.

product features

product characteristic

2.IP65 cabinet design, dimple plates for food contact parts;

4.60° steep discharge chute makes sure products discharge smoothly;

6.Rotary rollers equipped between each linear feeder pan helps to dispense the long soft products into feed hoppers.

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-6 | A14-1-6 |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 30P/M | 60P/M |

Hopper Volume | 2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 200V/1000W/50/60/Hz/10A | 220V/1500W/ 50/60Hz /12A |

Packing Dimension(mm) | 1620(L)X1100(W)X1420(H) | 1750(L)X1130(W)X1570(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing soft strip products such as noodles, rice noodles, bean sprout, etc

Company Features

1. Kenwei has been exporting our own high quality weight checker for decades.

2. Every piece of packaging equipment has to go through material checking, double QC checking and etc.

3. By providing the best quality and professional service, Guangdong Kenwei Intellectualized Machinery Co.,LTD. hopes building more cooperation relationship with every customer. Inquire online! The Kenwei plan would be to eventually become an internationally famous Multihead Weighers provider. Inquire online!