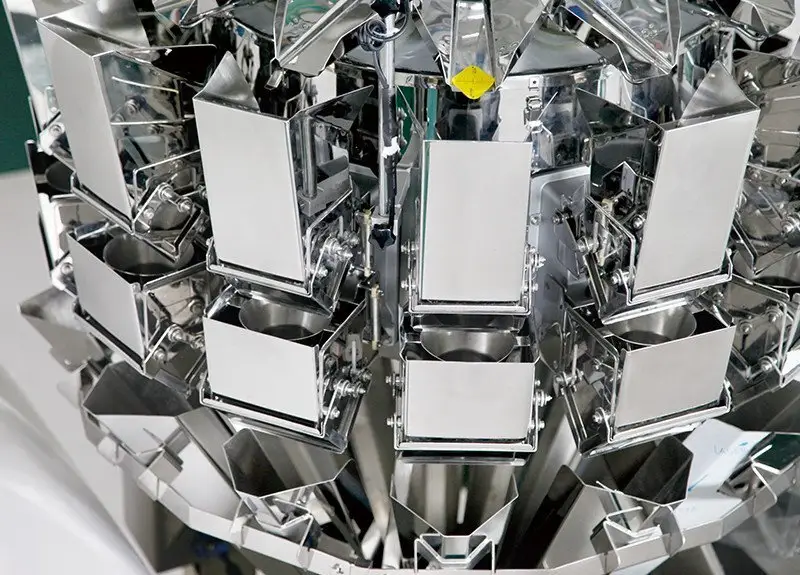

no spring weighing instruments standard weight checker Kenwei Brand 1st

1. Unmatched expertise of Kenwei enables us to serve our clients with utmost accuracy than our industry competitors. Operation of Kenwei packaging machine is safe and reliable

2. The adoption of weighing instruments method can cause vegetable weighing scales and satisfy production requirements. Kenwei packaging machine is cost-effective and quality-high

3. For weight checker, bag filling machine is also available upon request. Component replacement of each Kenwei packaging machine is simple and without trouble.

product features

product characteristic

2. Special linear feeder pan to make sure of feeding process.

4. Independent discharge chute can make sure that material discharge into packaging machine vertically.

Technical Specification

Model | JW-A10 | JW-A14 | JW-AS14 | JW-AM14 |

Identify Code | A10-1-9 | A14-1-9 | AS14-1-9 | AM14-1-9 |

Weighing Range | 10-1000g | 10-1500g | 3-200g | 10-3000g |

Accuracy | X(0.5) | X(0.5) | X(0.5) | X(1) |

Max Speed | 30P/M | 60P/M | 60P/M | 60P/M |

Hopper Volume | 2.5L | 2.5L | 0.5L | 5L |

Control Panel | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device |

Driving System | Step Motor | Step Motor | Step Motor | Step Motor |

Power Requirement | 220V/2000W/ 50/60Hz /12A | 220V/2000W/ 50/60Hz /12A | 2200V/1100W/ 50/60Hz /10A | 220V/2000W/ 50/60Hz /12A |

Packaging Dimension (mm) | 1620(L)*1100(W)*1420(H) | 1750(L)*1130(W)*1420(H) | 1190(L)*970(W)*950(H) | 2195(L)*1380(W)*2060(H) |

Gross Weight | 490kg | 490kg | 240kg | 650kg |

Applications

It is suitable for weighing stick shaped products, such as sausage, salty sticks, chopsticks, pencil,etc. max 200mm length.

Company Features

1. Zhongshan Multiweigh Packaging Machinery Co., Ltd owns manufacturing facilities.

2. Zhongshan Multiweigh Packaging Machinery Co., Ltd make every effort to have weighing instruments in this weight checker. Get quote!