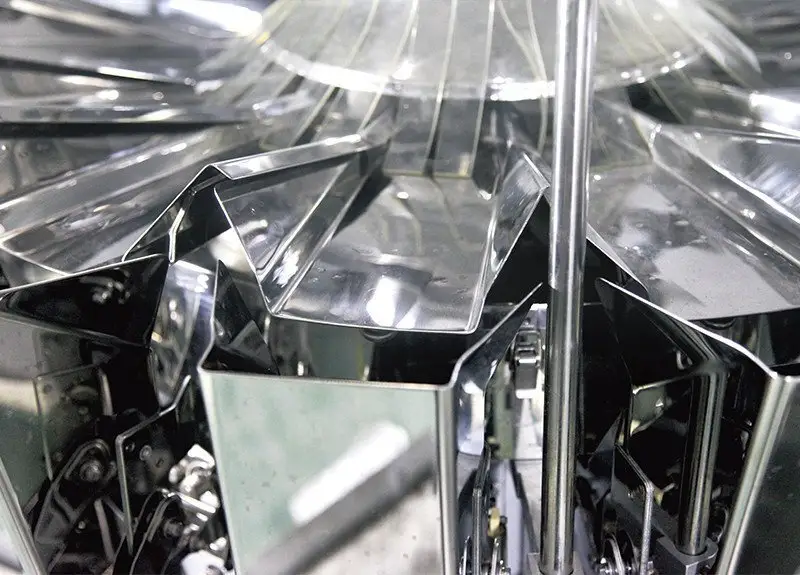

steel packaging machine easy to disassemble for materials with high viscosity Kenwei

-

v s

1. The raw materials of Kenwei food packing machine price in india are strictly provided by reliable suppliers. These materials undergo a thorough cleaning, filtering, and grading process.

2. The product has a certified quality and a stable and reliable performance.

3. The product is known for durability and has a longer functional life.

4. The use of this product is conducive to meeting the needs of social manufacturing. It not only increases the output rate, but also reduces labor costs.

5. Thanks to its fuel efficiency, the product greatly helps companies reduce CO2 emissions during operation and increase greener footprint in the long run.

14 head counting multihead weigher with a unique number of bags number of special procedures, the use of non-segregated inclined grooves, effectively avoid material clogging, suitable for coffee bags, jelly, biscuit bags and other small bags of packaging materials, bag weighing. The fastest number of bags is 40 bags per minute. It is easy to operate and can be chosen in many languages and is suitable for the global market.

product features

product characteristic

Equipped with a especially designed central cone, rotary top cone can dispense the products into each linear feeder pan evenly;

Equipped with both weighing and counting softwares;

Technical Specification

Model | JW-A12 | JW-A14 |

Identify Code | A12-1-2 | A14-1-2 |

Weighing Range | 10-30PCS | 10-30PCS |

Accuracy | 0PCS | 0PCS |

Max Speed | 30P/M | 40P/M |

Hopper Volume | 2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1700(L)X1100(W)X1130(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 470kg | 490kg |

Applications

It is specially designed for counting projects, such as tea bags, coffee bags, cereal and soybean, milk powder, hardwares , plastic , etc.

Company Features

1. Ranking top in packaging machine industry, Kenwei is popular in the market.

2. Manufactured by our progressive technology, bagging machine is of exquisite performance.

3. We value sustainability. We spare no efforts to raise awareness of sustainability issues among our employees, material suppliers, and our customers. Regarding the effect of pollution on the environment, we have come up with some corresponding strategies. For instance, we will take effluent and wastes disposal seriously to prevent pollution on the specific type of plants or species. We insist on our managing principle of surviving based on quality and improving based on innovation. We will enhance learning about world-cutting-edge manufacturing techniques and keep our own way of innovation. We want to operate in a safe, efficient and ethical way, protecting the planet and supporting the communities we work in while widening the value we offer to our customers.

Common products manufactured with HF welding method are blister case packing , pvc bags welding ,sports shoes vamp , logo marks , foam embossing , tarpaulins, tents, ceilings, advertising outdoor banners, waterbeds, inflatable boats, drip and blood bags, tensile structures, conveyor belts, rain clothing, etc.

What materials can be HF welded ?

The material most common in high frequency welding in PVC (something called simply vinyl) and PU (polyurethane) , leather , foam , mixed material ect . The material can be thick or thin, reinforced or coated. It can also be plain, coloured or structure/patterned.

Polyvinylchlorde (PVC) and polyurethanes (PU) are the most common thermoplastics that are weldabele by HF also it is possbile to perform HF welding on other types of materia inculding naylon, PA, ABS, modified TOP, PETG, but particular attention should be pay on working parameters. HF welding is not suitable for PTFE, polycarbonte, polystyrne, polyethylene or polypropylene. Howeve, a special type of mixed fabrics have been produced recently, which have the capability to be HF welded.

Scop of application:

1.Leather goods: purses, passport bags, belts, leather gifts, leather suits and other small leather goods;

2.Luggage: briefcases, briefcases, travel bags, handbags, computer bags, etc.

3.This book: notepad, million manual, business log, efficiency manual, address book, manager folder, etc .;

4.Leather case: Apple ipad 2 leather manufacturing, leather holster, imitation leather holster, leather products (leather box), digital products holster, electronic products holster, communications products holster, medical equipment products,

Other: camera bags, CD bags, etc., cell phone bags, cell phone wipes, blister cardboard packaging (such as toothbrushes, dental floss packaging), shoe materials, trademarks, straps and so on.

High frequency welding machine application:

Mainly used in plastic, plastic such as PET, PETG, GAG, PVC and other double-sided plastic packaging, plastic + paper card packaging soft silk box production, toothbrush packaging, dolls, leather straps need to be welded and cut product. The high frequency fusing machine with simultaneous welding and cutting function can also be used in the products of EVA cloth leather, leather, OPP, TPU, PU, hot water bag, strap, strap and so on. The machine manufactured by the machine feel comfortable, nice, suture exquisite.