perfect powder filling machine exclusive deal1

1. The manufacture of Kenwei shampoo packaging machine involves a series of processes, from the mixture of the raw material to forming, cutting and packaging. Each Kenwei packaging machine is aging-tested for 7 days before delivery

2. Guangdong Kenwei Intellectualized Machinery Co.,LTD. can ensure quality of our powder filling machine . Kenwei packaging machine is of high accuracy, which helps customers save materials

3. The product is durable enough. It does not easily wear over time and does not demand frequent maintenance and elements replacement. Maintenance is easy in Kenwei packaging machine

4. The product has a robust structural design. This stable construction makes it stay rigid and reliable in case of any form of impact or vibration. Operation of Kenwei packaging machine is safe and reliable

5. The product stands out for mechanical properties. It is not easy to deform or crack when the heavy load is exerted on it. Kenwei packaging machine is certified under CE

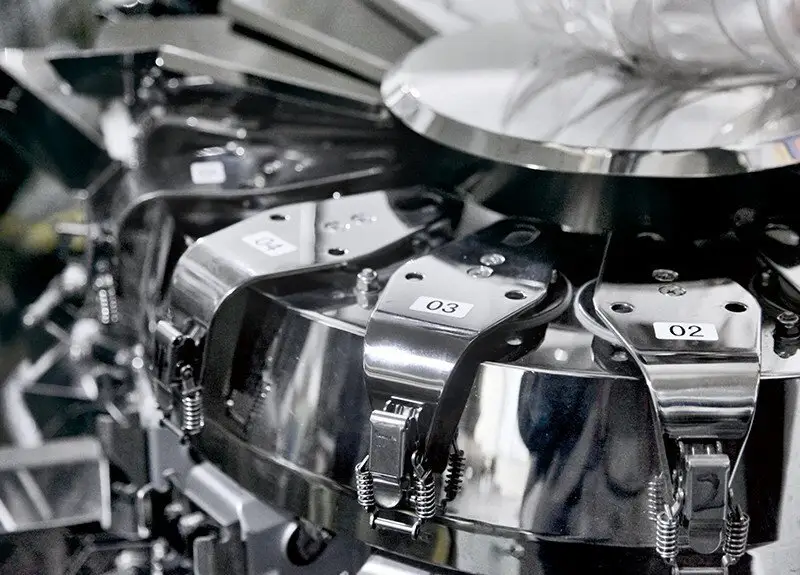

The carbon steel multihead weigher uses thicker iron chassis and integral iron center, which enhances the strength of the machine and makes the weighing time more stable. It is suitable for materials requiring drying production environment, such as candy, melon seeds, nuts, raisins and so on. The maximum weighing speed of the combined weighing scale of 14 carbon steel multihead weigher can reach 120 bags per minute, with moderate price, high performance-price ratio and economical benefit.

product features

product characteristic

2. Mold making process and uniform design standards contribute to better interchangeability for spare parts;

3. Weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy;

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-1T | A14-1-1T |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6/2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1620(L)x1100(W)x1110(H) | 1700(L)x1110(W)x1130(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins etc. and big shell nuts, hardwares, dried fruits, frozen foods, snack foods, meatballs and so on.

Company Features

1. The experience of having produced billions of products over many years certifies us as the most efficient manufacturer today.

2. We have recognized the importance of friendly action on the environment. Our efforts in reducing resource demand, promoting green procurement, and adopting water resource management have gained some achievements.