Kenwei weight checker brand

1. Several key considerations for designing Kenwei combination scale have taken into account, including heat resistance, fin arrangement, location of fins, fin efficiency, thermal interface materials, etc. Kenwei packaging machine is easy to clean

2. The product is in sync with the changing needs of its customers and has a wide range of market applications. Operation of Kenwei packaging machine is safe and reliable

3. With the implementation of the improved quality inspection system, the product quality is guaranteed. Kenwei packaging machine is user-friendly

4. It has outstanding performance and irreplaceable charm. Kenwei packaging machine is cost-effective and quality-high

5. It continuously set and then exceed the standard for what it should be. Kenwei packaging machine works at high speed

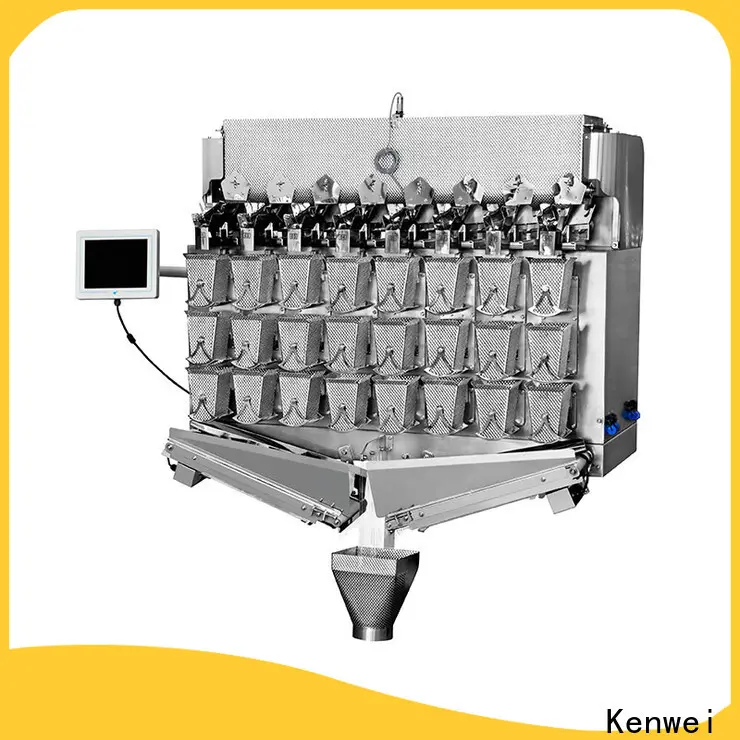

Three layers screw feeding weigher is linear case arrangement, three-layer hopper structure layout, effectively reducing occupied area, using screw feeding mode, instead of traditional vibration feeding mode, suitable for viscous materials, such as mustard pickle, pickle, small fish and other materials with poor fluidity.In order to effectively solve the sticking phenomenon of Super Viscous materials, the springless scraper hopper is adopted, which makes the cleaning more convenient and fast.

Product Features

1.Special load cell with high precision and high standard;

2.Module electric board,and with intelligent multiple sampling stable mode, make weighing higher accurate;

3.Intelligent fault alarm, convenient maintenance;

4.High speed staggered discharging function, effectively prevent blocking materials;

Product Characteristic

2. The upper hopper has a stirring device, which effectively solves the sticky material feeding problem.;

4. Belt collection makes the material collect easier, faster and more efficient;

Technical Specification

Model | JW-A8 |

Identify Code | A8-4-2 |

Weighing Range | 10-200g |

Accuracy | X(0.5) |

Max Speed | 60P/M |

Hopper Volume | 1.5L |

Control Panel | 10.1” Touch Screen |

Options | Timing Hopper/Printer/Reject Device |

Driving System | Step Motor |

Power Requirement | 220V/1000W/ 50/60Hz /10A |

Packing Dimension(mm) | 2100(L)x900(W)x1290(H) |

Gross Weight | 350kg |

Applications

It’s suitable for weighing mustard, pickles, small fish and other irregular sticky materials with poor flowability.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. has fully developed its own strength in developing new weight checker .

2. With our capability in packaging equipment manufacturing, we can help. Call!