Kenwei stability filling machine with high quality for spicy fish

- Kenwei provides comprehensive and professional services in accordance with the actual needs of customers.

1. We have special team to take charge of design for filling machine .

2. This product has passed through a rigorous testing and obtained certifications.

3. Our perfect quality control systems insure high quality and reliability of this product.

4. filling machine from Guangdong Kenwei Intellectualized Machinery Co.,LTD. has been positively affirmed by society and costumer.

5. By means of perfect system and advanced management, Guangdong Kenwei Intellectualized Machinery Co.,LTD. will ensure all production completed on schedule.

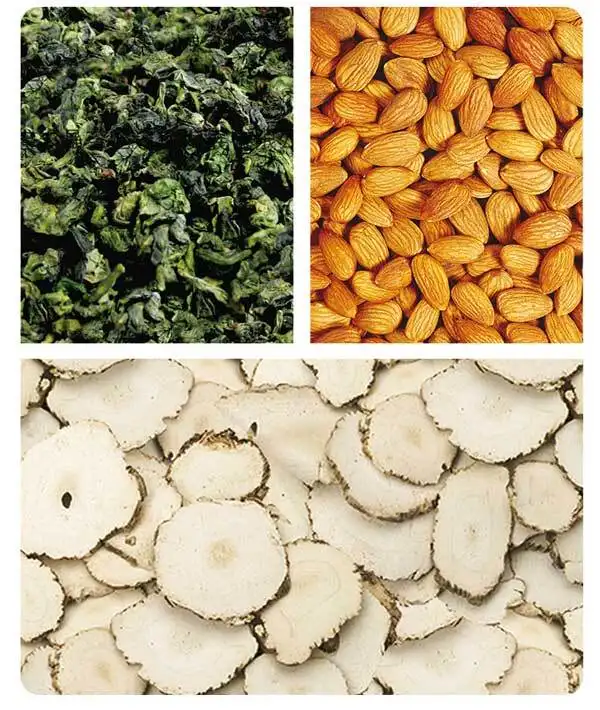

24 head mixing multihead weigher is a weighing equipment with 24 weighing hoppers for mixing four kinds of materials. It uses separate hoppers for mixing formula materials. It meets the requirements of two-in-one, three-in-one and four-in-one. It is suitable for granular materials with good fluidity, such as tea, beans, coffee beans and monosodium glutamate.

product features

product characteristic

2. Separate main vibrator,control the thickness of product independently

Technical Specification

Model | JW-A24 | JW-A24 |

Identify Code | A24-2-1 | A24-2-2 |

Weighing Range | 5-240g | 5-240g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 60P/M(Mix 4 Products) | 60P/M(Mix 3 Products) |

Hopper Volume | 0.5L | 0.5L |

Control Panel | 10.1”Touch Screen | 10.1”Touch Screen |

Options | Dimple Plate/Timing Hopper/Printer | Dimple Plate/Timing Hopper/Printer |

Driving System | Step Motor | Step Motor |

Power Requirement | 220V/1500W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1800(L)x1250(W)x1110(H) | 1800(L)x1250(W)x1110(H) |

Gross Weight | 440kg | 440kg |

Applications

It is suitable for weighing small granules such as seeds, tea, coffee beans etc..

Company Features

1. With years of development, Guangdong Kenwei Intellectualized Machinery Co.,LTD. has been one of the leading producer and distributor of weigher definition in the industry. We are known for providing high-quality products.

2. Guangdong Kenwei Intellectualized Machinery Co.,LTD. has a considerable manufacturing capacity with dozens of sets of filling machine processing equipment.

3. Customer satisfaction is Kenwei's principle of service! Call! In order to further enhance the core competitiveness, Kenwei lays more emphasis on the innovation of our vacuum packaging machine . Call! Guangdong Kenwei Intellectualized Machinery Co.,LTD. will carry forward the fine spirit of national industry. Call! It is Guangdong Kenwei Intellectualized Machinery Co.,LTD.'s goal to seek the excellent quality. Call!

Major characteristics:

This non-metal filling machine specially designed for strong acid and alkali product,such as: hydrochloric acid products,bleach.

(1)PLC controlled ,friendly touch screen control.

(2) Famous brand electrical and pneumatic components used to guarantee machines quality and long lfie service time.

(3) Vacuum suck back for dripping can be special designed for foamy product.

(4) All wetted parts are made of non-metal materials,which anti-foamy.

(5)Not only whole filling heads can be adjusted,but each filling head can be fine-adjusted respectively.

(6.Bottle inlet counting,quantative filling,bottle outlet counting ,and serious motions can be done automatically.

(7)Simple structure,easy operation, Low noise ,reliable running, accurate filling.

Technical parameter:

NO. | Items | Performance |

01 | Power Supply | AC 220V ;50Hz or 380V; 50Hz |

02 | Power | 1.5Kw |

03 | Suitable containers | Container mouth diameter: ≥Φ18mm |

Container height:100mm-300mm | ||

Container diameter:30mm-100mm | ||

04 | Number of filling nozzles | 12(may customized) |

05 | Productivity | ≤6000bottles/hour (Take 100ml water as test) ≤2500bottles/hour (Take 1000ml water as test) |

06 | Pneumatic (air -operated) source | 0.33-0.50 Mpa clean and Stable compressed air |

07 | Material density: | 0.6-1.3 |

08 | Machine weight | 650Kg |

09 | Dimension | 2000mm×1200mm×2300mm |

Application products: