Kenwei shrink wrap machine wholesale

1. Different high technologies are applied in the development of Kenwei home food packaging equipment . It is developed and upgraded under technologies such as mechanical systems technology, automatic control technology, sensing technology, and servo-drive technology. Kenwei packaging machine records less than 0.5% failure rate within 1 year

2. With this product, workers are more dedicated to their work and have higher working efficiency, which eventually helps increase the overall productivity. Kenwei packaging machine is of high accuracy, which helps customers save materials

3. This product has the advantages of long service life and stable performance. High precision molds and excellent components are adopted in Kenwei packaging machine

4. Products reach the advanced quality level of the industry. Operation of Kenwei packaging machine is safe and reliable

5. Several tests were performed at each stage of production to ensure consistency in product quality. It is easy and convenient to operate Kenwei packaging machine

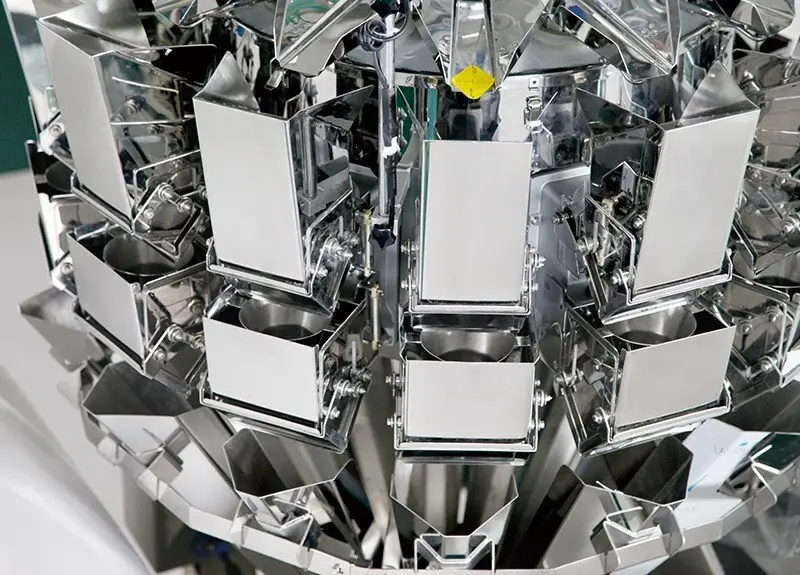

The strip multihead weigher adopts an independent inclined groove, which keeps the material in a vertical state and keeps the integrity of the strip material to the greatest extent. It is suitable for weighing strip materials such as sausages, finger cakes, long biscuits and chopsticks. There are many types of long-strip combination weighing scale, according to your material requirements can be selected.

Product Features

Product Characteristic

2. Special linear feeder pan to make sure of feeding process.

4. Independent discharge chute can make sure that material discharge into packaging machine vertically.

Technical Specification

Model | JW-A10 | JW-A14 | JW-AS14 | JW-AM14 |

Identify Code | A10-1-9 | A14-1-9 | AS14-1-9 | AM14-1-9 |

Weighing Range | 10-1000g | 10-1500g | 3-200g | 10-3000g |

Accuracy | X(0.5) | X(0.5) | X(0.5) | X(1) |

Max Speed | 30P/M | 60P/M | 60P/M | 60P/M |

Hopper Volume | 2.5L | 2.5L | 0.5L | 5L |

Control Panel | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device |

Driving System | Step Motor | Step Motor | Step Motor | Step Motor |

Power Requirement | 220V/2000W/ 50/60Hz /12A | 220V/2000W/ 50/60Hz /12A | 2200V/1100W/ 50/60Hz /10A | 220V/2000W/ 50/60Hz /12A |

Packaging Dimension (mm) | 1620(L)*1100(W)*1420(H) | 1750(L)*1130(W)*1420(H) | 1190(L)*970(W)*950(H) | 2195(L)*1380(W)*2060(H) |

Gross Weight | 380kg | 490kg | 240kg | 750kg |

Applications

It is suitable for weighing stick shaped products, such as sausage, salty sticks, chopsticks, pencil,etc. max 200mm length.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is skilled at producing and supplying quality shrink wrap machine for several years. Our quality is our company name card in packing machine china industry, so we will do it best.

2. We have a top R&D team to keep improving quality and design for our vacuum packaging machine .

3. At present, most of the packing machine price series produced by us are original products in China. We are committed to the environmental sustainability of our operations. We have reduced the water utilization of our factory in order to prevent excessive utilization of water sources.