Kenwei powder filling machine brand1

1. To guarantee a good electrical contact, Kenwei powder filling machine is carefully treated both in components soldering and oxidation. For example, the metal part of it has been exquisitely handled with paint to avoid oxidation or corrosion. High precision molds and excellent components are adopted in Kenwei packaging machine

2. The product is suitable for a variety of applications and has a great market prospect as it is popular now in the market for great economic benefits. Operation of Kenwei packaging machine is safe and reliable

3. The product is an essential tool for hazardous materials. Its excellent leakage resistance can prevent the escape of toxic fumes to the surroundings. Each Kenwei packaging machine runs stably

4. It delivers good building energy performance. Relative performance is measured when possible using various analysis software such as Ecotect and EnergyPlus. Designs are tuned based on the results. Kenwei packaging machine is cost-effective and quality-high

5. The product is intelligent. It is built with microprocessors to monitor pressure, voltage, current, temperature, and to dissipate heat automatically. Kenwei packaging machine works at high speed

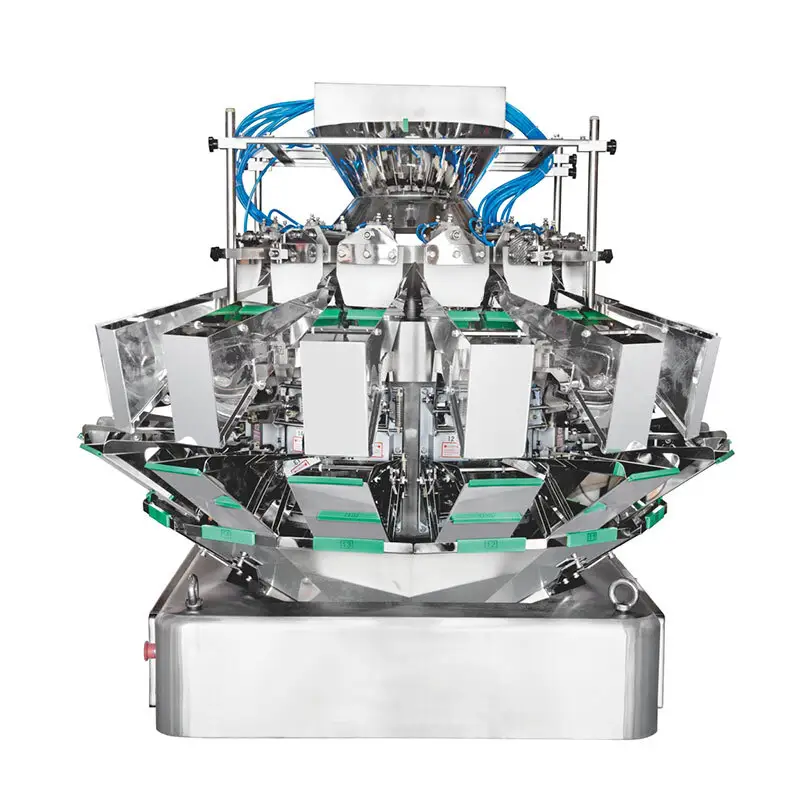

Multi Head Scale Breakage-Proof Multihead Weigher adopts an inclined weighing bucket, which can shorten the falling height in advance and protect the integrity of weighing materials. It is suitable for weighing fragile materials such as fresh fruits, ice cubes, biscuits and peanuts. The Multi Head Scale Breakage-Proof Multihead Weigher uses a hopper with a capacity of 3 liters, and the maximum weighing speed reaches 120 packs per minute.

Product Features

Product Characteristic

4.Gently Angle the chute to allow the material to slide completely to the next step.

5.Reduce the falling height in all directions, so that the material can be completely protected.

Technical Specification

Model | JW-A10 | JW-A14 | |

Identify Code | A10-2-9 | A14-2-9 | |

Weighing Range | 10~1000g | 10-1000g | |

Accuracy | X(0.5) | X(0.5) | |

Max Speed | 40P/M | 60P/M | |

Hopper Volume | 3L | 3L | |

Control Panel | 10.1” Touch Screen | 10.1”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | Step Motor | |

Power Requirement | 200V/1400W/50/60/Hz/6A | 200V/2200W/50/60/Hz/10A | |

Packing Dimension(mm) | 1620(L)X1080(W)X11050(H) | 1700(L)X1200(W)X1150(H) | |

Gross Weight | 400kg | 490kg | |

Applications

It is suitable for weighing crunchy materials such as fresh fruit ice crepes and dried peanutsetc.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. has strong design team, technology team and development team to launch novel ideas on powder filling machine .

2. We aim to supply the best weigher with most competitive price. Inquire now!