Kenwei packaging machine supplier1

1. Kenwei shampoo packaging machine has been given various innovative and practical designs thanks to our unremitting R&D efforts. Component replacement of each Kenwei packaging machine is simple and without trouble

2. This product can perform a large number of risky work in a risky industrial production environment. Therefore, workers are not easily injured or overworked. High precision molds and excellent components are adopted in Kenwei packaging machine

3. This product has good strength. Various types of load such as steady loads (dead loads and live loads) and variable loads (shock loads and impact loads) have been considered in designing its structure. Maintenance is easy in Kenwei packaging machine

4. There is sufficient strength inside this product. Force analysis is performed prior to manufacture to find the forces acting on each element. And the best-suited materials are chosen to withstand these forces. Each Kenwei packaging machine runs stably

5. The product is distinguished by earthquake resistance. Made of heavy-duty materials and designed with strong construction, it can resist any form of sharp vibrations.

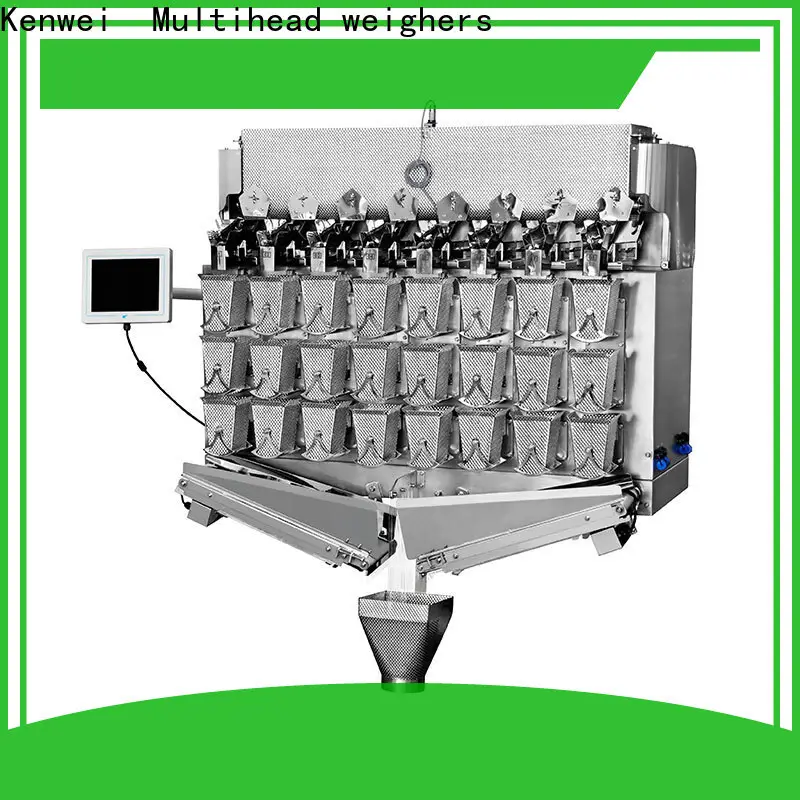

Three layers screw feeding weigher is linear case arrangement, three-layer hopper structure layout, effectively reducing occupied area, using screw feeding mode, instead of traditional vibration feeding mode, suitable for viscous materials, such as mustard pickle, pickle, small fish and other materials with poor fluidity.In order to effectively solve the sticking phenomenon of Super Viscous materials, the springless scraper hopper is adopted, which makes the cleaning more convenient and fast.

Product Features

1.Special load cell with high precision and high standard;

2.Module electric board,and with intelligent multiple sampling stable mode, make weighing higher accurate;

3.Intelligent fault alarm, convenient maintenance;

4.High speed staggered discharging function, effectively prevent blocking materials;

Product Characteristic

2. The upper hopper has a stirring device, which effectively solves the sticky material feeding problem.;

4. Belt collection makes the material collect easier, faster and more efficient;

Technical Specification

Model | JW-A8 |

Identify Code | A8-4-2 |

Weighing Range | 10-200g |

Accuracy | X(0.5) |

Max Speed | 60P/M |

Hopper Volume | 1.5L |

Control Panel | 10.1” Touch Screen |

Options | Timing Hopper/Printer/Reject Device |

Driving System | Step Motor |

Power Requirement | 220V/1000W/ 50/60Hz /10A |

Packing Dimension(mm) | 2100(L)x900(W)x1290(H) |

Gross Weight | 350kg |

Applications

It’s suitable for weighing mustard, pickles, small fish and other irregular sticky materials with poor flowability.

Company Features

1. Through constant technological invention, Guangdong Kenwei Intellectualized Machinery Co.,LTD. is at a leading position in the packaging machine business. We have our own designers and engineers. They work on product design and sample making. They are highly flexible to the changing market trends, which enables them to act and design products that are satisfactory to customers.

2. Our company has a skilled workforce. The workers have enough knowledge about what they are doing. This helps reduce the number of errors and helps us keep customers satisfied.

3. We have established strong and stable business relationships both at home and abroad. We have established a customer base in the United States, Australia, and some European countries. We aim to be leader in the package scale industry. Please contact.