Kenwei nospring multi weigher nospring indoor

-

v s

1. There are different types of food packing machine for our customer's choice.

2. Products under the supervision of professionals, through strict quality inspection, to ensure product quality.

3. Strict and perfect quality control system, to ensure that products with the best quality and performance production.

4. As a professional food packing machine manufacturer, Kenwei will be confident enough to provide food weight scale and multi weigher .

5. Kenwei now has kept a long-term friendly relationships with our customers for years of experience.

product features

product characteristic

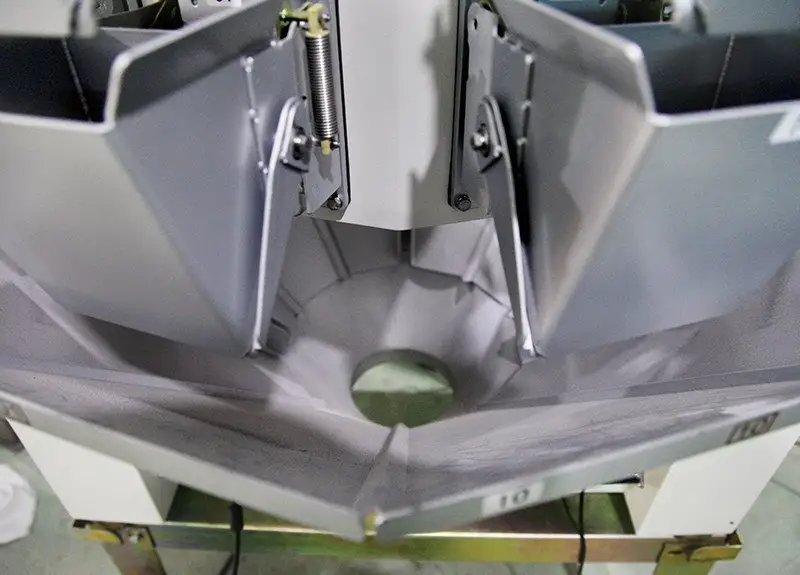

2. Tailor-made thickened hopper.

Technical Specification

Model | JW-AM10 | JW-AM14 |

Identify Code | A10-1-15 | A14-1-15 |

Weighing Range | 10-2000g | 10-3000g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6L | |

Control Panel | 7'' Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/50Hz/60Hz/10A | 220V/1000W/50Hz/60Hz/10A |

Packaging Dimension (mm) | 1620(L)X1100(W)X1420(H) | 1620(L)X1100(W)X1420(H) |

Gross Weight | 380kg | 480kg |

Applications

It is suitable for weighing small hardwares and plastic parts, length is less than 80mm, single piece weight is less than 100g.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is the backbone of the Chinese food packing machine industry.

2. Guangdong Kenwei Intellectualized Machinery Co.,LTD. has strong technical force and advanced management.

3. Kenwei has been always concentrating on the improvement of food weight scale . Ask! Continuous innovation of product technology is a fundamental part in Kenwei. Ask! Guangdong Kenwei Intellectualized Machinery Co.,LTD. is committed to the idea of foodpack . Ask!

TP-SG-240 Horizontal Automatic Bag Packing Machine

GENERAL DESCRIPTION:

SG-240 Automatic Packing Machine is an new designed packing machine special for pre-made bags. It’s used for filling and sealing flat bag, stand-up bag, hung-hole bag and strange-shape bag. With different

filling head, it can fill and pack materiel like powder, liquid, granule, paste etc. Now it’s widely applied in food, beverage, pharmaceutical, daily chemical and other industries.

On this machine, filling and sealing are two separated system. They will be integrated by PLC, so you can

adjust it according to material, bag shape and size to make it compatible for fully automatic production line.

Powder filling head

Granule filling head

WORKING PROCESS:

Pre-made pouch stack → Flip-out and pouch-picking unit → Zipper open → Pouch open → Air flushing →

First fill → Second fill → Pouch stretching → Top seal I → Top seal II → Finished product → Outlet

CHARACTERISTICS:

1. Easy to operate,adopt advanced PLC from Germany SCHNEIDER, mate with touch screen and electric control system, the man-machine interface is friendly

2. Frequency conversion adjusts the speed: this machine uses frequency changer equipment, can be adjusted within the range according to the needs of reality in production

3. Safety device: Machine stop at abnormal air pressure, heater disconnection alarm

4. It machines with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust

5. Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

6. With different feeders changed to pack solid, liquid, thick liquid ,powder and so on.

7. Use no oil vacuum pump and plastic bearing; avoid polluting the environment in the production.

8. The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on film.

PARAMETERS:

TP-SG-240 Horizontal Bag Packing Machine | |||

Pouch origin | Pre-made | Packing speed | 30-60ppm |

Pouch transporting | intermittent | Power(w) | 5500 |

Bag size(mm) | 100*120(min) | Air consumption | 400NL/min |

| 240*320(max) | Dimension(mm) | 3600(L)*1100(W)*1500(H) |

Pouch volume | 2000ml | Weight(kg) | 1800 |

NOTE:

1. Delivery Period: 35 days after receipt of down payment

2. Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery

3. Guarantee Period: 12 months

4. Package: seaworthy plywood carton