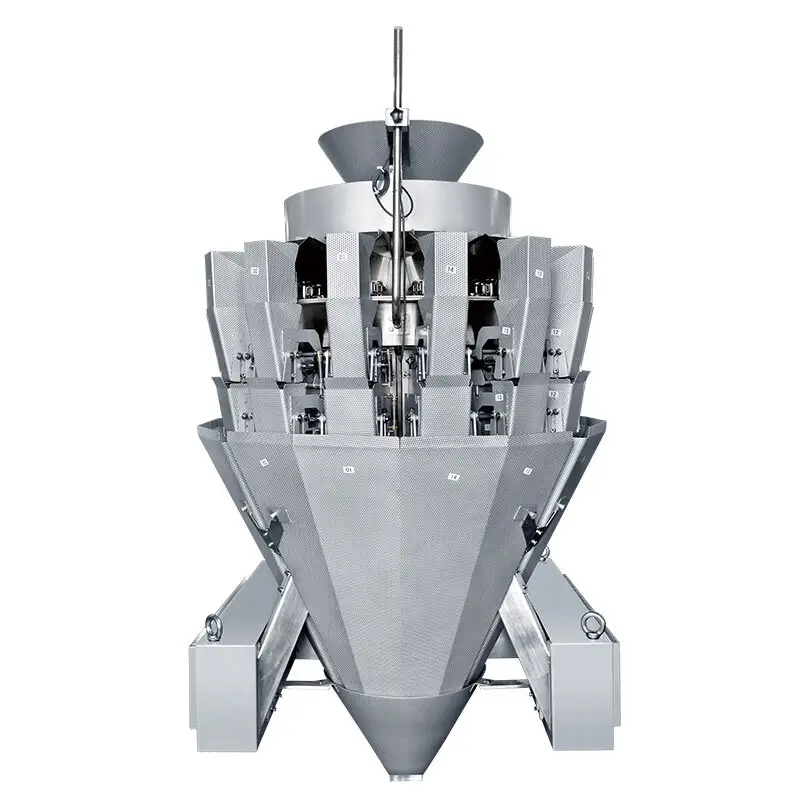

Kenwei frozen packing machine price with high-quality sensors for spicy fish

Model:

JW-A14

MOQ:

1set

Payment:

L/C, T/T

Place of Origin:

China

Brand:

Kenwei

Identify Code:

A14-2-8

Weighing Range:

10-200g

Accuracy:

X(0.5)

Max Speed:

50P/M

Hopper Volume:

1L

Control Panel:

10.1'' Touch Screen

Options:

Dimple Plate/Timing Hopper/Printer/Reject Device

Driving System:

Step Motor

Power Requirement:

220V/1500W/ 50/60Hz /10A

Packing Dimension(mm):

1750(L)x1130(W)x1590(H)

Gross Weight:

490kg

Material

304 stainless steel

Certification

CE, OIML, SGS

Availability

OEM/ODM

Delivery Time

7-30days

Start Port

zhongshan port

Supply Ability

500 sets/year

Product Comparison

Kenwei has the ability to meet different needs. packaging machine is available in multiple types and specifications. The quality is reliable and the price is reasonable.Compared with other products in the same category, Kenwei's packaging machine has the following advantages.

Application Scope

Kenwei's weight checker can meet the different needs of customers.Kenwei insists on providing customers with one-stop and complete solution from the customer's perspective.

1. packing machine price is made by new environmentally-friendly material.

2. The product is reliable in operation. It is not prone to cause some dangerous effects such as electric current, and sudden stop.

3. With the development of society, our packing machine price are also manufactured to meet the higher demands of customers.

PRODUCT FEATURE

bg

PRODUCT CHARACTER

bg

IP65 waterproof case is adopted, small dimple plate material is adopted for contact materials, and 60 degree feeding chute is used to make materials fall smoothly.

The scraper hopper can effectively solve the problem of material sticking on the hopper

Double point material inspection is more accurate and effective to control the thickness.

Two layers screw feeding scheme can control materials more precisely and is suitable for various viscous materials.

TECHNICAL SPECIFICATION

bg

| Model | JW-A14 |

|---|---|

| Identify Code | A14-2-8 |

| Weighing Range | 10-200g |

| Accuracy | X(0.5) |

| Max Speed | 50P/M |

| Hopper Volume | 1L |

| Control Panel | 10.1”Touch Screen |

| Options | Dimple Plate/Timing Hopper/Printer/ Reject Device |

| Driving System | Step Motor |

| Power Requirement | 220V/1500W/ 50/60Hz /10A |

| Packing Dimension(mm) | 1750(L)*1130(w)*1590(H) |

| Gross Weight | 490kg |

APPLICATION

bg

It is suitable for weighing mustard, pickles, small fish etc., which with poor flowability.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD., since it's inception, has developed long-term customers over the world.

2. Produced by weigher definition technology, our packing machine price are of high performance for its finest quality.

3. Our goal is to maximize the value of our company. Therefore, we will continue to work to create valuable products that will help create a brighter future for society. Get more info! Full of passion and power, our mission is to make real change to consumers and businesses around the world every day. Get more info! We are committed to increasing our market share in existing markets, investigating new product opportunities, and aggressively pursuing business opportunities in new markets.

Product Description

BAG OPENINHG

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators.

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators.

They are rotated to the fill area and opened.

TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch

TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch

detection the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting

the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through

the "open-gate''

FILLING

During filling, pouches are held in place with our “posi-hold” gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place"

FILLING

During filling, pouches are held in place with our “posi-hold” gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place"

eliminating wrinkles, folded corners and non aligned seals

MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator

MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator

lights signal all cycle processes for easy monitoring.

SPECIFICATIONS

Product Description

BAG OPENINHG

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators.

Pouches are individually removed from the cartridge with a unique combination of vacuum and pneumatic actuators.

They are rotated to the fill area and opened.

TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch

TRANSITION CHUTE

doubling as a timing bucket. product enters the transition chute while the bag is being opened below. Upon pouch

detection the chute enters the bag and opens its gate. Product is dispensed immediately, without spillage and protecting

the seal from contamination. Difficult product that easily bridges is dispensed into the pouch directly from the filler, through

the "open-gate''

FILLING

During filling, pouches are held in place with our “posi-hold” gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place"

FILLING

During filling, pouches are held in place with our “posi-hold” gripper system. This allows for heavy weights and shock loads

without disturbing bag Position

SEALING

Digitally controlled ribbed or flat constant heat seal bars give a integral attractive seal. Pouches are sealed ''in place"

eliminating wrinkles, folded corners and non aligned seals

MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator

MECHINE CONTROLS

System controls are fully solid state. utilizing a commercial Programmable Logic Controller [PLC] and pneumatics. Indicator

lights signal all cycle processes for easy monitoring.

SPECIFICATIONS

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Copyright © 2018 Guangdong kenwei Intelligent Machinery Co., Ltd.