Kenwei feeding packaging systems easy to disassemble for materials with oil

- Kenwei receives converted recognition from customers depending on good product quality and a comprehensive service system.

1. Our Kenwei packaging systems can be produced in various design styles and specifications.

2. The performance of packaging systems is stable, and the quality is reliable.

3. By using this product, everything under it looks more vibrant and lifelike. It brings a fresh look of the surrounding for me. - said one of the customers.

4. People have no worry that it is subject to getting a puncture and suddenly everything collapsing on them in the night.

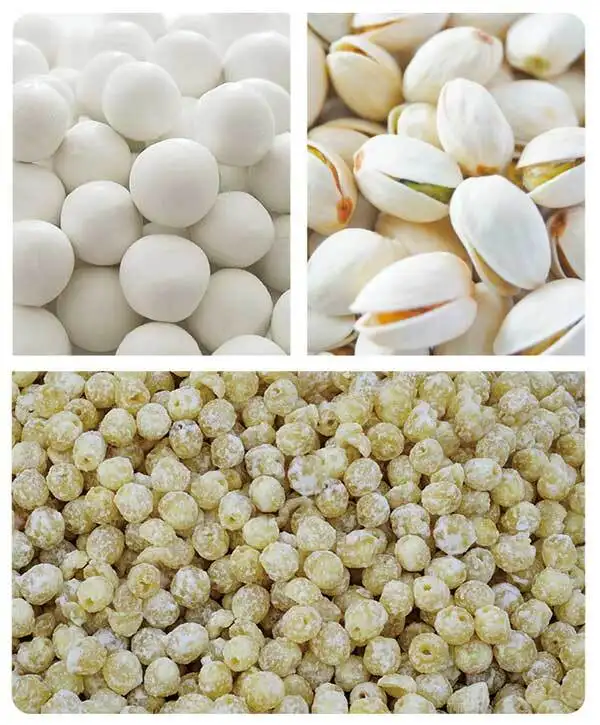

High speed weigher is a new spring-free aluminum shell design structure, double chute feeding combined with double high-speed hopper alternating feeding, greatly improve the speed of feeding, suitable for melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios and other materials weighing. The 18 heads high speed weigher is called the hopper with 2L, and the maximum weighing speed can reach 180 bags/min.

product features

product characteristic

Technical Specification

Model | JW-A14 | JW-A18 |

Identify Code | A14-3-1 | A18-3-1 |

Weighing Range | 10-1000g | 10-1000g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 130P/M | 180P/M |

Hopper Volume | 2.0L | |

Control Panel | 10.1''Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V1000W/50/60Hz/10A |

Packing Dimension(mm) | 1760(L)*1190(W)*1390(H) | 1950(L)X1650(W)X1650(H) |

Gross Weight | 500kg | 800kg |

Applications

It’s suitable for weighing seeds, peanuts, nuts, almonds, raisins, candy, pistachio, potato chips, dumplings and other granule, sheet, strip, round shape material.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. boasts years of excellent manufacturing expertise in packaging systems and has been regarded as one of the leading manufacturers in the industry.

2. Always aim high in quality of filling machine .

3. We are not focused on competing with other companies. We determine the market standard. This fact holds true when it comes to the characteristics and qualities of our individual products. We achieve sustainable development by reducing production waste. We have diverted our manufacturing and post-consumer waste solutions from landfill and waste valorization by incineration to higher value beneficial uses like recycling and upcycling. We have sustainability targets in place to reduce our already low impact on the environment. These targets covering general waste, electricity, natural gas, and water. Check it! Our goal is to add value to our customers, and we will always develop cost-effective product solutions to help our customers achieve their goals. Check it!