Kenwei fast shipping packaging equipment wholesale

1. Kenwei multihead weigher packing machine goes through meticulous designing. Factors such as the accuracy, surface finish and other related parameters for the machine elements are specified with great deliberation. It is easy and convenient to operate Kenwei packaging machine

2. With its special features and accessories, the product can further expedite and simplify the production process, which will contribute to saving on money.

3. The quality control is highlighted during production, ensuring the stable quality of the product. Kenwei packaging machine records less than 0.5% failure rate within 1 year

4. Manual inspection and equipment testing both have been carried out to ensure that the product is 100% qualified. Component replacement of each Kenwei packaging machine is simple and without trouble

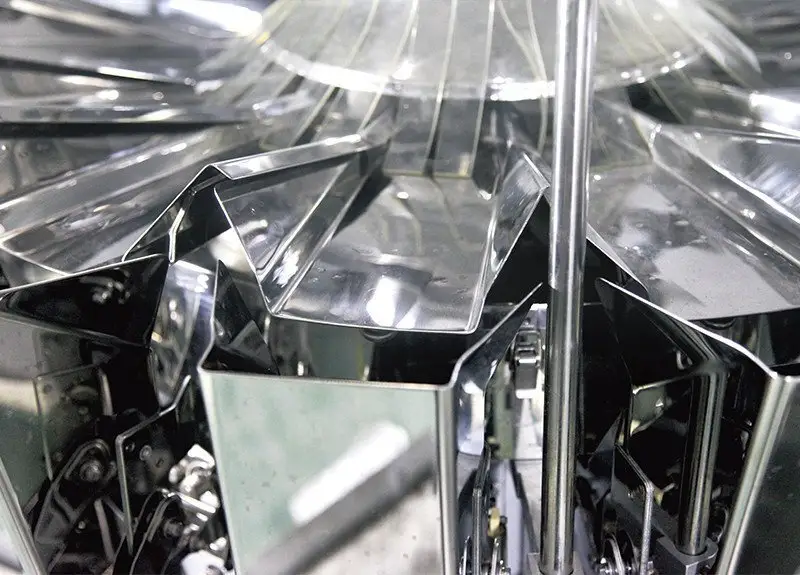

14 head counting multihead weigher with a unique number of bags number of special procedures, the use of non-segregated inclined grooves, effectively avoid material clogging, suitable for coffee bags, jelly, biscuit bags and other small bags of packaging materials, bag weighing. The fastest number of bags is 40 bags per minute. It is easy to operate and can be chosen in many languages and is suitable for the global market.

Product Features

Product Characteristic

Equipped with a especially designed central cone, rotary top cone can dispense the products into each linear feeder pan evenly;

Equipped with both weighing and counting softwares;

Technical Specification

Model | JW-A12 | JW-A14 |

Identify Code | A12-1-2 | A14-1-2 |

Weighing Range | 10-30PCS | 10-30PCS |

Max Speed | 30P/M | 40P/M |

Hopper Volume | 2.5L | |

Control Panel | 7” Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1700(L)X1100(W)X1130(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 470kg | 490kg |

Applications

It is specially designed for counting projects, such as tea bags, coffee bags, cereal and soybean, milk powder, hardwares , plastic , etc.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is equipped with strong research strength, having an R&D team dedicated to developing all types of new packaging equipment .

2. Kenwei has been constantly growing the service quality to enhance the satisfaction of foreign and domestic clients.