Kenwei fast shipping filling machine from China

1. Kenwei filling machine follows an extremely strict process in product design and development. Kenwei packaging machine is easy to clean

2. Our supplied service including process packaging machinery and automatic liquid pouch packing machine is offered by our professional service team. Operation of Kenwei packaging machine is safe and reliable

3. The product can provide uniform and faultless results. It can complete its task normally and reach the predetermined requirements without any failure. Kenwei packaging machine is widely used in food, pharmaceuticals, chemicals and other fields

4. The product features enough safety. Its mechanical parts are well encapsulated to guarantee no parts will toss out during operation. Kenwei packaging machine is user-friendly

5. The corrosion resistance of this product is prominent. Its surface is treated with a kind of mechanical paint, a solid film which adheres firmly to the surface to protect against corrosion. Kenwei packaging machine is manufactured based on industry standards

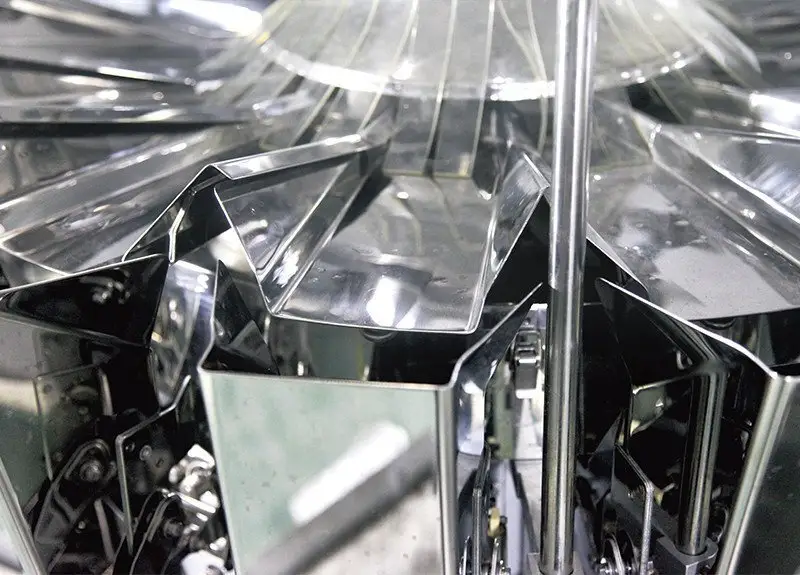

14 head counting multihead weigher with a unique number of bags number of special procedures, the use of non-segregated inclined grooves, effectively avoid material clogging, suitable for coffee bags, jelly, biscuit bags and other small bags of packaging materials, bag weighing. The fastest number of bags is 40 bags per minute. It is easy to operate and can be chosen in many languages and is suitable for the global market.

Product Features

Product Characteristic

Equipped with a especially designed central cone, rotary top cone can dispense the products into each linear feeder pan evenly;

Equipped with both weighing and counting softwares;

Technical Specification

Model | JW-A12 | JW-A14 |

Identify Code | A12-1-2 | A14-1-2 |

Weighing Range | 10-30PCS | 10-30PCS |

Max Speed | 30P/M | 40P/M |

Hopper Volume | 2.5L | |

Control Panel | 7” Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1700(L)X1100(W)X1130(H) | 1700(L)X1110(W)X1265(H) |

Gross Weight | 470kg | 490kg |

Applications

It is specially designed for counting projects, such as tea bags, coffee bags, cereal and soybean, milk powder, hardwares , plastic , etc.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is a strong filling machine enterprise full of competition.

2. Our work team are experts who have been experienced in snack pack field for years.

3. Over many years of development, our company adheres to the principle of good faith. We conduct business trade in accordance with fair and refuse any vicious business competition.