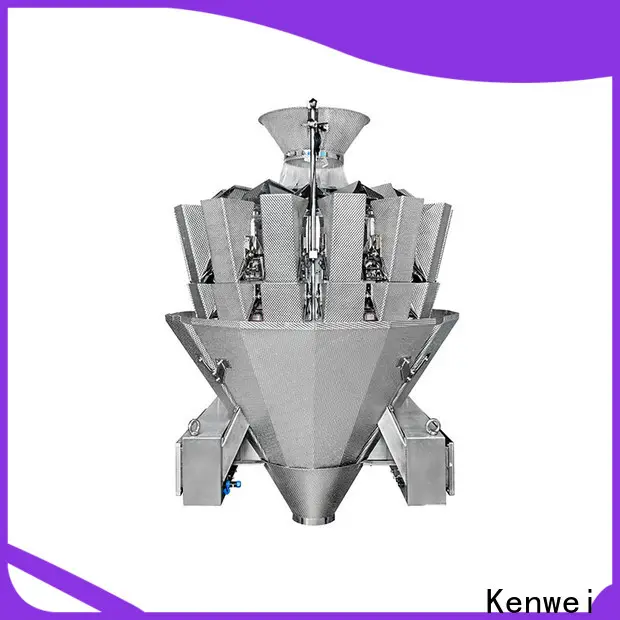

Kenwei cheap packing machine from China

1. Kenwei salt packaging equipment is produced in a room in which no dust and bacteria are allowed. Particularly in the assembly of its inner parts which directly contact with the food, no contaminant is permitted. Kenwei packaging machine records less than 0.5% failure rate within 1 year

2. The use of this product can effectively help reduce operation error, which not only ensures workers safety but also increases production efficiency. Each Kenwei packaging machine is aging-tested for 7 days before delivery

3. The product is equipped with all the safety systems. The function of automatic diagnosis enables it to detect the faults of the instruments by alarming. Kenwei packaging machine is environmental-friendly

4. The screen of this product features high resolution. Adopting the backlight technology in LCD production, the screen of this product generates little or no flicker. Component replacement of each Kenwei packaging machine is simple and without trouble

5. The surface of this product is highly resistant to scratch. It is carefully polished and impervious to any external influence. Each Kenwei packaging machine runs stably

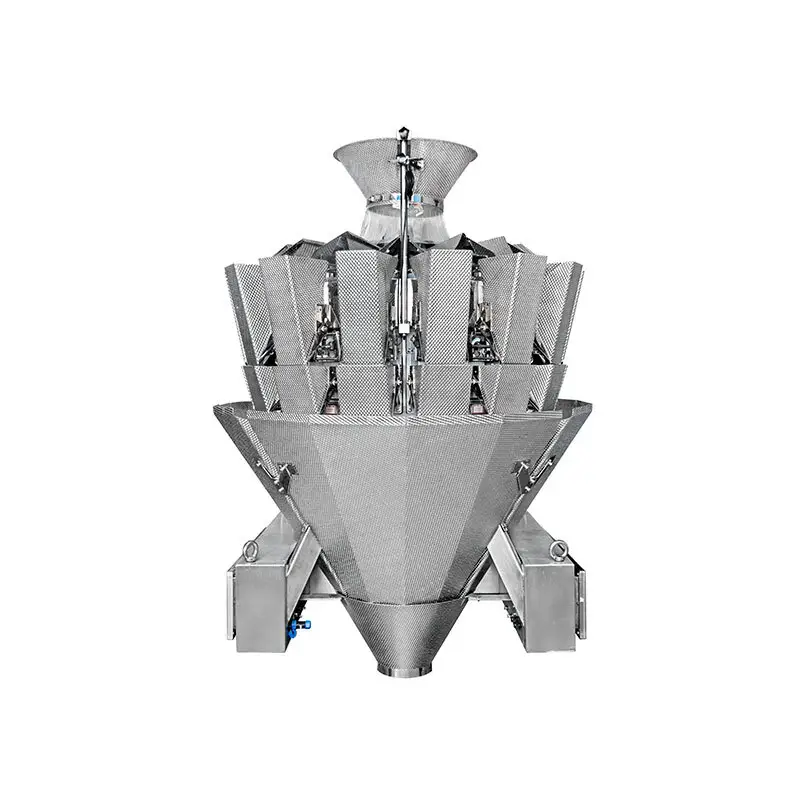

14 head anchovy fish multihead weigher are designed with single-door special hopper and anti-sticking design to ensure smooth flow of materials, prevent sticking and ensure weighing accuracy. They are suitable for weighing materials with high stickiness and high content, such as spicy fish-larvae, pickled duck, and other leisure snacks.

Product Features

Product Characteristic

2.Inclined special linear vibration pan to ensure smooth flowing of materials;

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-16 | A14-16 |

Weighing Range | 10-1500g | |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 40P/M | 60P/M |

Hopper Volume | 1.6L | |

Control Panel | 7” Touch Screen | |

Options | Timing Hooper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 110/220V/1000W/ 50/60Hz /8A | 110/ 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1620(L)X1100(W)X1420(H) | 1750(L)X1160(W)X1420(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for materials with high viscosity and with much oil,it easy to stick on

the hopper and material that can slide in the 60-angle discharged chute,such as spicy fish,sauce duck,etc.

.

Company Features

1. Our R&D team aids us to stay competitive in the markets. The team always keeps innovative and stays ahead of trends. They are able to research and analyze the products other businesses are creating, as well as the new trends within the industry.

2. We are intentional about sustainability. We incorporate sustainability into our company's development strategies. We will make this a priority in every aspect of business operations.