Kenwei automatic packaging machine easy operation for indoor/outdoor

1. Kenwei checkweigher manufacturers is attractive in design and exquisite in details.

2. packaging machine provides a new method to checkweigher manufacturers .

3. Innovative technologies, innovative products, and innovative services are the source of the Guangdong Kenwei Intellectualized Machinery Co.,LTD.'s sustainable development.

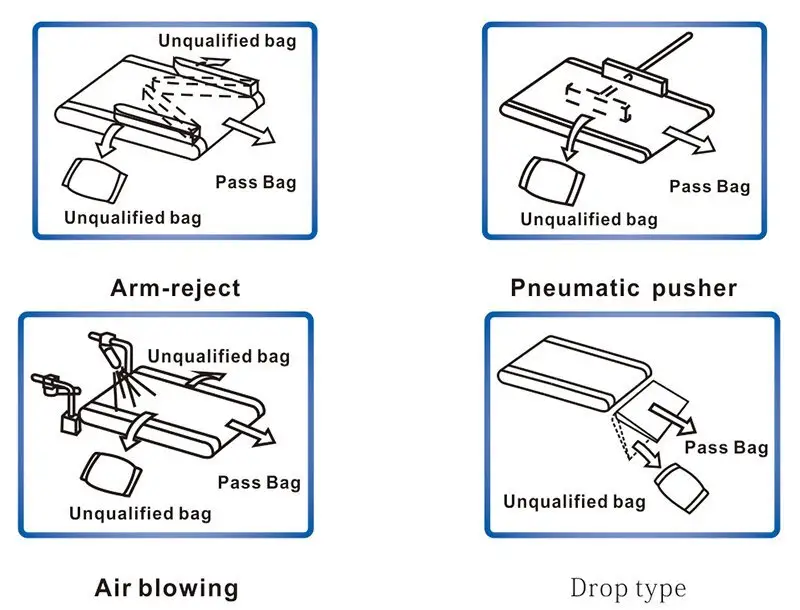

The check weigher is used to check whether the weight of a single product is in accordance with the set goal, and the sorting device automatically eliminates the substandard products. It has the eliminating methods of rocker arm, pneumatic push rod, blowing, sliding, etc. The maximum conveying speed of the sorting scale is 55 meters per minute, and it can handle many different packaging styles, including bulk paper bags, plastic bags, cartons, metallized film packaging, etc.

product features

Technical Specification

Model | JW-C200 | JW-C1000 | JW-C2000 |

Identify Code | C200-1-1 | C1000-1-1 | C2000-1-1 |

Weighing Range | 5-200g | 100-1000g | 10-2000g |

Accuracy | XIII(1) | XIII(1) | XIII(1) |

Max.Belt Speed | 55m/min | 52m/min | 52m/min |

Max.Speed | 100 PCS | 80/PCS | 80PCS |

Belt width | 150mm | 220mm | 300mm |

Belt Size | 350(L)*160(W)mm | 450(L)*220(W)mm | 450(L)*300(W)mm |

Power Requirements | 220V/ 500W / 50/60Hz | 220V/500W / 50/60Hz | 220V/500W / 50/60Hz |

Packing Dimension(mm) | 1250(L)*570(W)*1150(H) | 980(L)*800(W)*1290(H) | 980(L)*860(W)*1290(H) |

Reject Method | Air blowing | Air blowing/Air-reject/Pneumatic pusher/Slide type | |

Model | JW-C3000 | JW-C6000 |

Identify Code | C3000-1-1 | C6000-1-1 |

Weighing Range | 10-3000g | 10-6000g |

Accuracy | XIII(1) | XIII(1) |

Max.Belt Speed | 40m/min | 40m/min |

Max.Speed | 70PCS | 70 PCS |

Belt width | 400mm | 400mm |

Belt Size | 650(L)*400(W)mm | 650(L)*400(W)mm |

Power Requirements | 220V/700W/ 50/60Hz | 220V/700W/50/60Hz |

Packing Dimension(mm) | 1400(L)×950(W)×1530(H) | 1400(L)X950(W)X1530(H) |

Reject Method | Air blowing/Air-reject/Pneumatic pusher/Slide type | |

Applications

It is used to check whether the single bag weight is conformed to the preset weight or not and auto remove the unqualified products by the rejection device .

Company Features

1. Kenwei has gradually gained its popularity in packaging machine industry.

2. The development of manufacturing innovation industrial scale technology is very important for the development of weight checker.

3. Quality strategies remain our operational principle. We will invest more in sourcing higher quality raw materials and seek more delicate workmanship in our efforts to improve product quality. We aim to conduct all our activities within a framework of good corporate social responsibility (CSR) so that we may go above and beyond the obligations have to our business partners and our employees. To assume social responsibility, we have established a corporate sustainable development team to manage sustainable development with ESG elements at the core.

Export standard plywood package are supplied with well packed. we can make the packages according to customer's request. Sea packages or Air packages are both available.

Usually to ship DXD-420A Bean Sprouts Packaging Machine by sea way.

Use:

Suitable for automatic packaging particle materials like all kinds of sweets, chocolate, biscuits, peanuts, nuts,rice,grain,seeds,pistachio,coffee beans, lima beans,sugar,salt and desiccant.

Features:

1.Imported PLC control system, simple-operating, visual touch screw.

2.Servo film feeding system, correct register, sealing and cutting positions adopt automatic correction device, high automation.

3.Intelligent temperature controller is used, correct temperature control, ensure nice, smooth seal.

4.Perfect automatic alarming protective function, reduce the consumption up to the lowest.

5.When the machine is combined with metering equipments, full packaging process including automatic feeding, metering, bag filling, date printing and automatic counting is completed.

6.Type of bag making: according to customer's demand, the machine can produce pillow bags, punched hanging bags.

Main Technical parameter:

Packing speed | 15-70bags/min |

Bag-making size | (L)80-300mm(W)80-200mm |

Filling range | 100-1500g |

Packing materials | OPP/CPP PET/PE |

Film width | 180-420mm |

Film thickness | 0.04-0.08mm |

Air consumption | 0.36m3/min 0.6MPa |

Power supply | AC220V 50/60Hz 3.5kw |

Machine dimensions | (L)1750×(W)1050×(H)2200mm |

Machine weight | 600kg |