Kenwei 100% quality wrapping machine exclusive deal

1. The production process of Kenwei in line checkweigher mainly includes three parts. These parts, namely, sizing processing, glaze processing, and quality inspection, are all conducted under strict control and inspection.

2. The use of this product would contribute to a reduction in labor costs. Its high automation level allows a company to retain fewer operators, thereby saving on overhead. Kenwei packaging machine is easy to clean

3. The product is in high demand in the international market due to its high quality and good usability. Each Kenwei packaging machine is aging-tested for 7 days before delivery

4. To assure its durability, the product is strictly examined by our highly skilled QC professionals. Kenwei packaging machine works at high speed

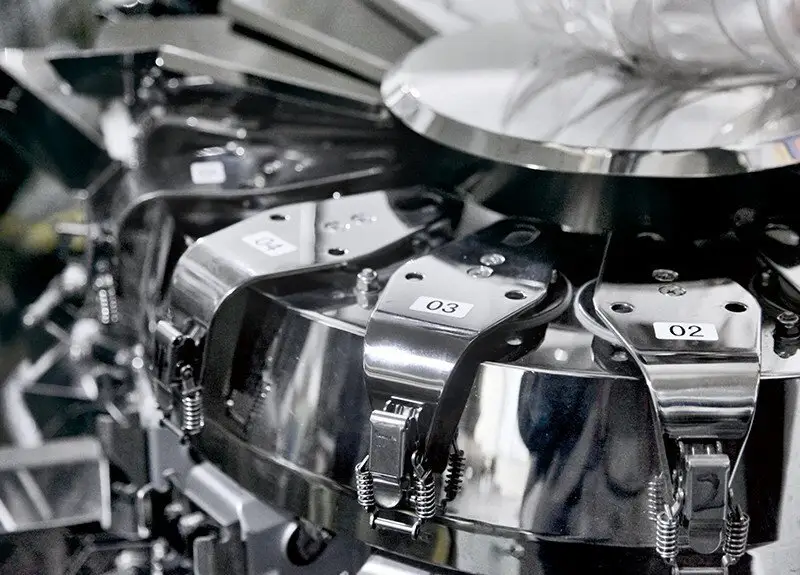

The carbon steel multihead weigher uses thicker iron chassis and integral iron center, which enhances the strength of the machine and makes the weighing time more stable. It is suitable for materials requiring drying production environment, such as candy, melon seeds, nuts, raisins and so on. The maximum weighing speed of the combined weighing scale of 14 carbon steel multihead weigher can reach 120 bags per minute, with moderate price, high performance-price ratio and economical benefit.

product features

product characteristic

2. Mold making process and uniform design standards contribute to better interchangeability for spare parts;

3. Weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy;

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-1T | A14-1-1T |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6/2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1620(L)x1100(W)x1110(H) | 1700(L)x1110(W)x1130(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins etc. and big shell nuts, hardwares, dried fruits, frozen foods, snack foods, meatballs and so on.

Company Features

1. Over the years, Guangdong Kenwei Intellectualized Machinery Co.,LTD. has developed quickly and become a strong competitor in the market. We primarily focus on the production of in line checkweigher .

2. Guangdong Kenwei Intellectualized Machinery Co.,LTD. has studied the new process of home food packaging equipment production.

3. We have set up a clear development goal: maintaining product superiority all the time. Under this goal, we will strengthen the R&D team, encourage them to make the best of other useful resources to enhance the competitiveness of products.