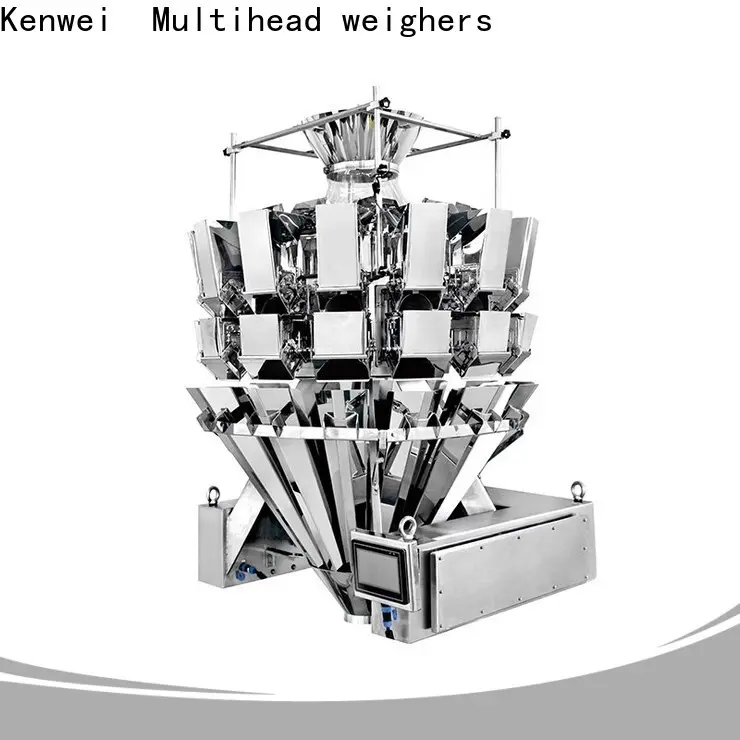

high quality package scale supplier

1. Kenwei pouch packing machine masala packing machine is designed using the optimum quality raw material as per industry guidelines.

2. This product will reduce the need for the workforce for its highly advanced system. It will directly cut down labor costs. High precision molds and excellent components are adopted in Kenwei packaging machine

3. This product has good strength. It is made of heavy-duty welded metal, which makes contribution to the excellent hardness and provides strong impact resistance to fight against deformation. Component replacement of each Kenwei packaging machine is simple and without trouble

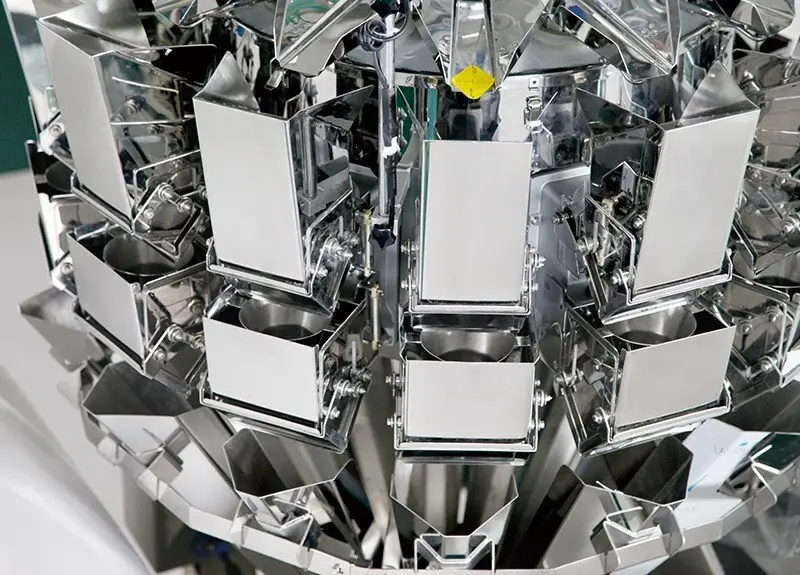

The strip multihead weigher adopts an independent inclined groove, which keeps the material in a vertical state and keeps the integrity of the strip material to the greatest extent. It is suitable for weighing strip materials such as sausages, finger cakes, long biscuits and chopsticks. There are many types of long-strip combination weighing scale, according to your material requirements can be selected.

Product Features

Product Characteristic

2. Special linear feeder pan to make sure of feeding process.

4. Independent discharge chute can make sure that material discharge into packaging machine vertically.

Technical Specification

Model | JW-A10 | JW-A14 | JW-AS14 | JW-AM14 |

Identify Code | A10-1-9 | A14-1-9 | AS14-1-9 | AM14-1-9 |

Weighing Range | 10-1000g | 10-1500g | 3-200g | 10-3000g |

Accuracy | X(0.5) | X(0.5) | X(0.5) | X(1) |

Max Speed | 30P/M | 60P/M | 60P/M | 60P/M |

Hopper Volume | 2.5L | 2.5L | 0.5L | 5L |

Control Panel | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen | 7'' Touch Screen |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device | Dimple Plate/Timing Hopper/Printer/Reject Device |

Driving System | Step Motor | Step Motor | Step Motor | Step Motor |

Power Requirement | 220V/2000W/ 50/60Hz /12A | 220V/2000W/ 50/60Hz /12A | 2200V/1100W/ 50/60Hz /10A | 220V/2000W/ 50/60Hz /12A |

Packaging Dimension (mm) | 1620(L)*1100(W)*1420(H) | 1750(L)*1130(W)*1420(H) | 1190(L)*970(W)*950(H) | 2195(L)*1380(W)*2060(H) |

Gross Weight | 380kg | 490kg | 240kg | 750kg |

Applications

It is suitable for weighing stick shaped products, such as sausage, salty sticks, chopsticks, pencil,etc. max 200mm length.

Company Features

1. Kenwei is more and more mature in the development and operation of package scale . Our factory houses advanced production facilities and lines including materials processing lines and assembly lines which can ensure our continuous and stable productivity.

2. Lawfull granted with a production certificate, the company is allowed to manufacture and sell products to the public by the China Administration for Industry and Commerce. This certificate is directly related to public safety, human health, and life and property security, which means customers can be assured that what we produce and sell are safe and secure.

3. We have a team of professional manufacturing members. They are familiar with complex and sophisticated new tools, such as robotic systems or all kinds of advanced machine. We truly embrace sustainable development. We proactively reduce production waste, increase resource productivity, and optimize material usage.