dust-proof packaging machine combination with high quality for materials with slight viscosity

1. Kenwei packaging machine is professionally designed considering the following factors: the functionality of the control system, engineering forces, life cycle, utility, and manufacturability.

2. It has good strength. Its materials have the required toughness to resist deformation under stress and resist fracture due to high impact load.

3. The product can replace labor to achieve mechanization and automation in production. It is widely applied in light and heavy industries.

Grain scale is suitable for fast and high-precision weighing of large-weight materials, such as corn, soybean, rice, rice, barley, wheat, and other grain industry materials. The action of feeding, filling and unloading bags of the grain scale is automatically completed by the grain quantitative weighing. The operation of the grain scale is simple. The operator only needs to cover the bags and touch the pocket travel switch.

product features

product characteristic

2.Three feeding level and special control algorithms make the weighing speed more quickly and higher accuracy.

Technical Specification

Model | JW-AX1 |

Identify Code | XL1-2-1 |

Weighing Range | 5~50kg |

Accuracy | 10-50g |

Max Speed | 7~11P/M |

Control Pannel | 7.0’’ Touch Screen |

Options | Conveyor Belt /bag sealer |

Power Requirement | 220V / 80W / 50/60HZ / 0.4A |

Packing Dimension(mm) | 1250(L)*1150(W)*2280(H) |

Gross Weight | 150kg |

Applications

It’s suitable for weighing corn, soybeans, rice, barley, wheat, buckwheat, peanuts, beans and other small granules in food industry,light industry, chemical industry in bulk weight.

Company Features

1. By supplying packaging machine and professional service, Kenwei now ranks top in the market.

2. Our company is supported by a dedicated R&D team. Their expertise enhances the planning of product optimization. This allows us to perfectly complete the planning of products.

3. To Guangdong Kenwei Intellectualized Machinery Co.,LTD., technology innovation is a strategic engine for an enterprise’s sustainable development. Get more info! Upholding combination scale proves to be the source of new impetus for the sustained and healthy development of Kenwei. Get more info!

Function:

The machine cans automatic finish

- Ø Measuring

- Ø Bag-making

- Ø Filling

- Ø Sealing

- Ø Cutting

- Ø Date printing

Features

1.Multiple fashion bag shapes, various sealing patterns, and a variety of filling method;

2.Advanced film unwind and bag forming technique;

3.Full servo technologies and microcomputer control,with stable operation;

4.Mobile touch screen; safety doors.

5.Different filling devices come up with different packing for powder, liquid, grain, and cream.

6.You can get swift, precise and sanitary packing for any products

7.make products much more attractive

Main characteristics of the equipment

Item | The main characteristics of the body |

Host Frequency Control System | Import Mitsubishi Frequency Control, stable and reliable operation, even in low-speed torque loads of great change in circumstances, the same excellent operation. |

Bag system | The mechanism of the making bag, seal and the filling is relatively independent of the system. The two systems are linked through the machine and the PLC (PLC) to coordinate joint. As a result, can be adapted to different objects packaging, packaging externality size. |

Product packaging system | With sealing of packaging materials (polyethylene film, the multi-layer composite film), the automatic completion of the bag, measures such as filling and sealing packaging process of fully automated production equipment. bags of self stand-up, 3 side and4 side flat bag, big belly bag can be completed. Selection of different types of filling, packaging can be different. |

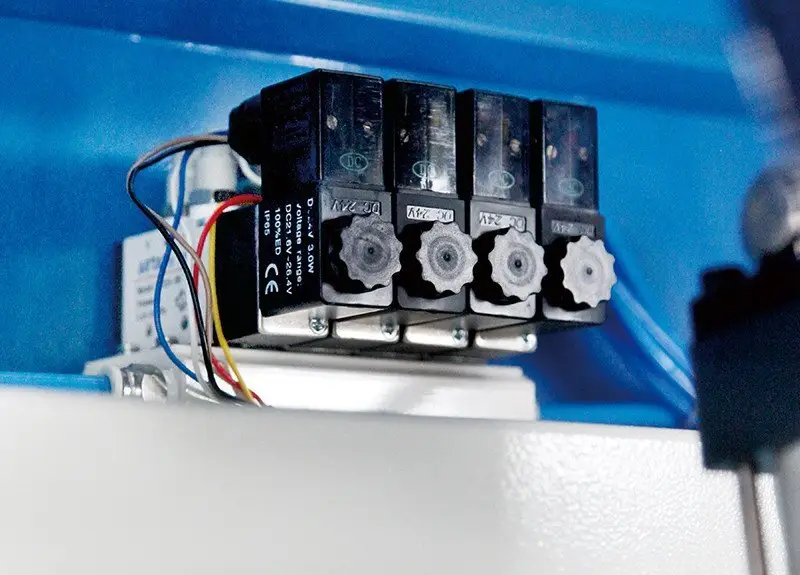

Integrated Control System | Adopt PLC programmable a computer program controller, frequency converter, high-integration, the ability to control, reliable operation. Application of touch-screen technology to enable the operation of the machine more reliable and convenient. Photoelectric sensors, encoders, switches, close to on-off import advanced sensors, so that the mechanical and electrical machinery are the perfect performance. |

Technical Parameters

Packing material | Complex film |

Packing products | powder, grain, liquid, mixed product |

Producing speed | 40-80P/M |

Precision in packing | within +/-1.5% |

Pouch width | 90mm-180mm (adjustable) |

Pouch height | 100mm-250mm (adjustable) |

Packing Volume | 250g, 500g (adjustable) |

Roil diameter | 600 ml (adjustable) |

Electricity consumption | 8 kw |

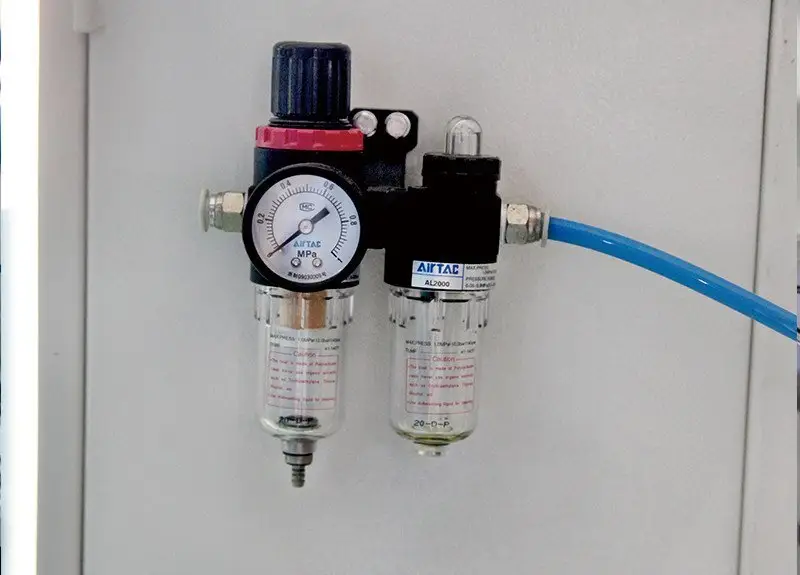

Air Consumption | 0.6m3/min |

Voltage | 380V |

Maxchine Weight | 2500 kg |

Machine Size | 8000mm*1100mm*1500mm(customed) |

wooden case packaging for pouch horizontal packing machine

after we received your deposit we will deliver your machines within 30 days.