custom package scale from China

1. Kenwei peanut packaging equipment goes through a series of production processes. They involve CAD/CAM design, prototyping, milling, turning, fabrication, welding, spraying, and commissioning. It is easy and convenient to operate Kenwei packaging machine

2. Guangdong Kenwei Intellectualized Machinery Co.,LTD. strictly follows the ISO9001 international quality certification system for production management. Kenwei packaging machine is cost-effective and quality-high

3. The product is highly valued for its unparalleled quality and practicality. Kenwei packaging machine is environmental-friendly

4. The quality of this product is guaranteed and has many international certificates, such as ISO certificates. Maintenance is easy in Kenwei packaging machine

5. This product has excellent performance and reliable quality. High precision molds and excellent components are adopted in Kenwei packaging machine

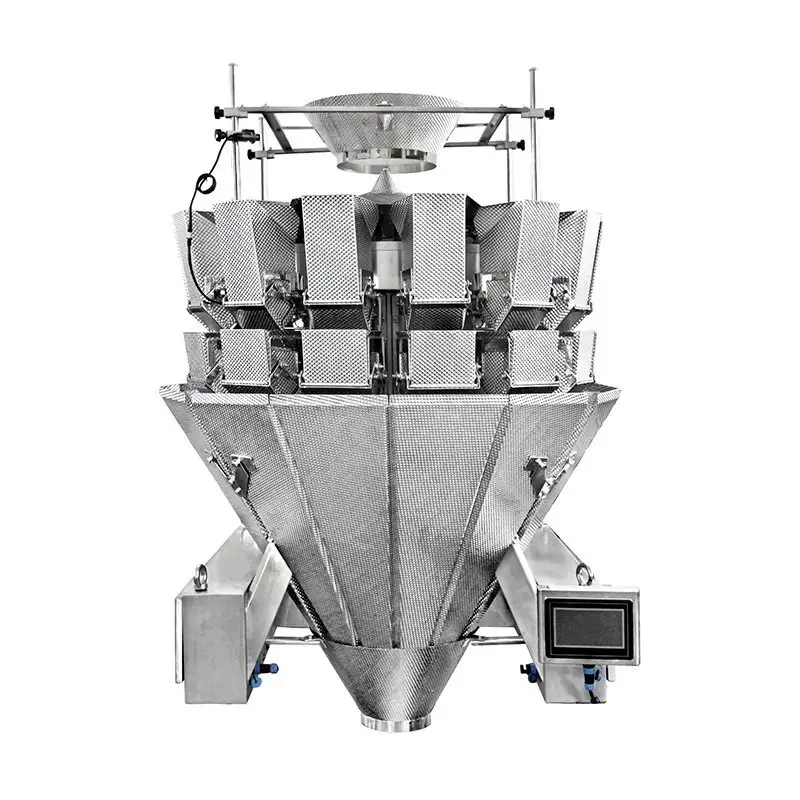

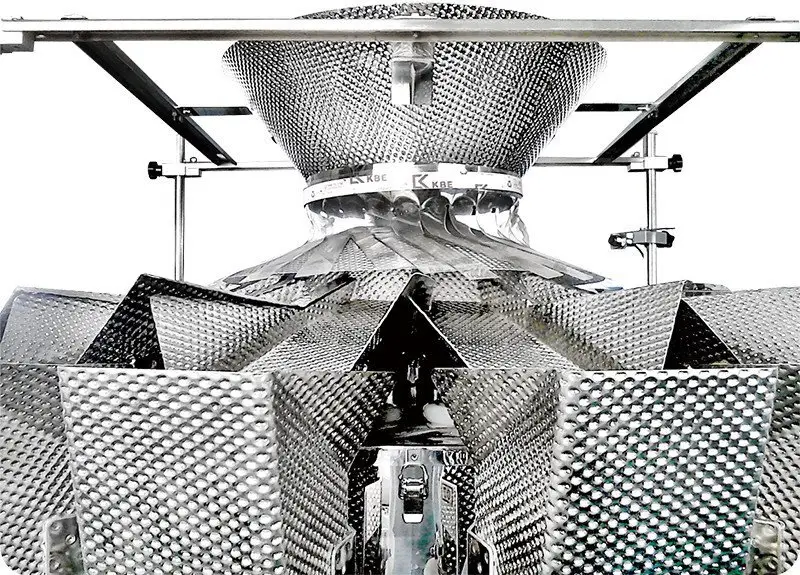

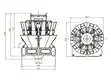

Cheese Combination Scale is a weighing equipment which can weigh soft and sticky materials such as cotton candy and preserved fruit besides cheese. The cheese scale uses a small twisted groove with 60 degrees angle, which makes the material fall smoothly and effectively controls the phenomenon of sticky material. The maximum weighing speed can reach 100 packs per minute.

Product Features

Product Characteristic

2. Enhanced linear vibrator improves the flowability of material.

3. The declinational special linear vibrator pan, ensure smooth feeding.

5. Optional weighing type material detection, accurate control of feeding time, material thickness, to ensure the accuracy of the weighing;

6. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time.

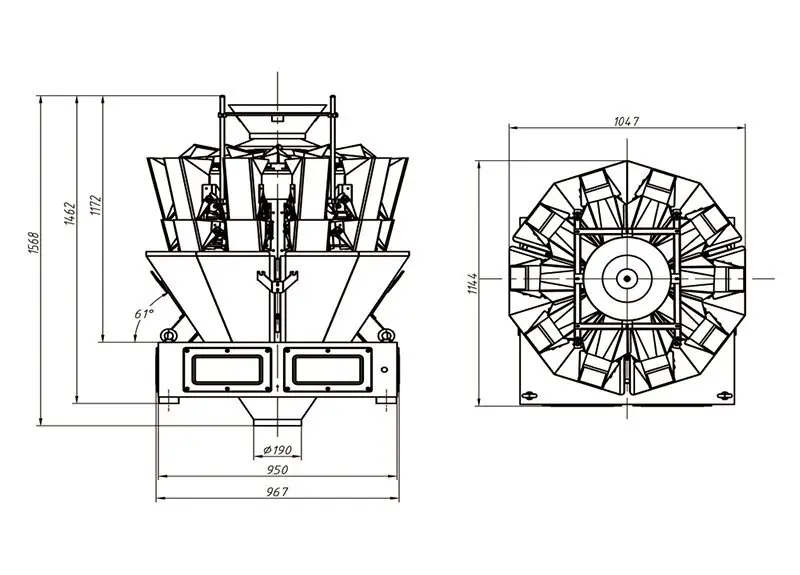

Technical Specification

Model | JW-A10 | JW-A12 | JW-A14 |

Identify Code | A10-1-12 | A12-1-12 | A14-1-12 |

Weighing Range | 10-1000g | 10-1500g | 10-1500g |

Accuracy | X(0.5) | X(0.5) | X(0.5) |

Max Speed | 60P/M | 100P/M | 100P/M |

Hopper Volume | 1.6L / 2.5L | ||

Control Panel | 7'' Touch Screen | ||

Options | Timing Hopper/Printer/Reject Device | ||

Driving System | Step Motor | ||

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1200W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packaging Dimension (mm) | 1620(L)X1100(W)X1110(H) | 1700(L)X1110(W)X1130(H) | 1750(L)X1130(W)X1420(H) |

Gross Weight | 380kg | 450kg | 490kg |

Applications

It is suitable for weighing soft and sticky material, such as cheese, jelly candy,cotton candy, preserved fruits, candied fruit, etc.

Company Features

1. With our broad sales network, we have exported our products to many countries while establishing a reliable strategic partnership with many large and famous companies.

2. We constantly find ways to relieve and reduce our impact on the environment. We make progress in minimizing the use of energy and water and reducing production waste.