convenient filling machine powder with high quality for materials with oil

- Since the inception, Kenwei has always been adhering to the service purpose of 'integrity-based, service-oriented'. In order to return our customers' love and support, we provide high-quality products and excellent services.

1. Kenwei home made packing machine goes through meticulous designing. Factors such as the accuracy, surface finish and other related parameters for the machine elements are specified with great deliberation.

2. The product has an anti-aging property. It contains a large number of anti-aging agents including antioxidants, metal inhibitors, and heat stabilizers.

3. The product features highly stable mechanical properties. It has been treated with heat or cold temperature to enhance its properties.

4. This product can replace human beings to complete dangerous tasks, which greatly relieves the pressure and labor of workers in the long run.

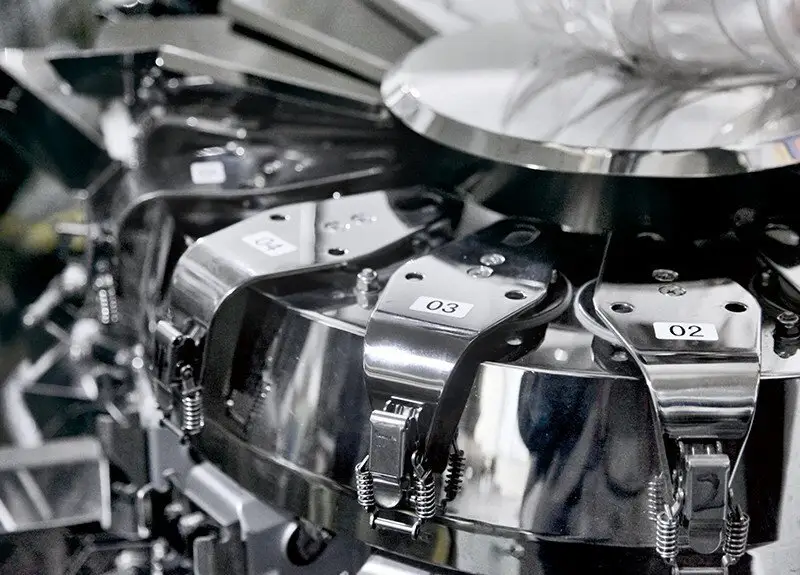

The carbon steel multihead weigher uses thicker iron chassis and integral iron center, which enhances the strength of the machine and makes the weighing time more stable. It is suitable for materials requiring drying production environment, such as candy, melon seeds, nuts, raisins and so on. The maximum weighing speed of the combined weighing scale of 14 carbon steel multihead weigher can reach 120 bags per minute, with moderate price, high performance-price ratio and economical benefit.

product features

product characteristic

2. Mold making process and uniform design standards contribute to better interchangeability for spare parts;

3. Weighing type for material detection is available, which can make accurate control of feeding time & material thickness and ensure weighing accuracy;

Technical Specification

Model | JW-A10 | JW-A14 |

Identify Code | A10-1-1T | A14-1-1T |

Weighing Range | 10-1000g | 10-1500g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 65P/M | 120P/M |

Hopper Volume | 1.6/2.5L | |

Control Panel | 7”Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1000W/ 50/60Hz /10A | 220V/1500W/ 50/60Hz /10A |

Packing Dimension(mm) | 1620(L)x1100(W)x1110(H) | 1700(L)x1110(W)x1130(H) |

Gross Weight | 380kg | 490kg |

Applications

It is suitable for weighing leisure foods such as candy, seeds, jelly, pet foods, puffy foods, pistachio, peanuts, nuts, raisins etc. and big shell nuts, hardwares, dried fruits, frozen foods, snack foods, meatballs and so on.

Company Features

1. Guangdong Kenwei Intellectualized Machinery Co.,LTD. is one of point key enterprises in Chinese profession's filling machine industry.

2. We are proud to have an excellent technical team to produce snack pack with outstanding performance.

3. Kenwei adheres to the tenet of cultivating corporate culture always. Ask! By following the professional service process, Kenwei always provide the best service for customers. Ask!

Features:

1. The Juice Bottling Equipment is using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change of the bottle-shaped become easier.

2. The machine 's bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The machine is specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. The machine is high-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. The machine is spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. The machine host adopt advanced PLC automatic control technology ,the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

7. The machine equipped with a constant temperature system, temperature controlled and circumfluent automatically.

Flow Chart for juice filling machine:

Details:

1. Water treatment system:

According to the customer requirements and the source water quality, we adopt different equipment to produce pure water, mineral water,etc. The main equipments are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter,water tank,etc. The treatment capacity is 0.5-50 ton/hour. It can effectively get rid of muddy organic matter, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of microorganism and some of heavy metal ion in the water, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water.

2. Bottle blowing machine:

Here we can supply both semi auto and full auto bottle blowing machine according to your needs.

Full auto machine we do 2 cavities, 4 cavities, 6 cavities and 8 cavities.

3. Juice blending system

mixing system: Syrup melting tank→Juice preparing tank with thermal & blender→Double heads filter→Juice de-oxygenation machine→Juice homogenizer→High level juice tank→UHT Sterilizer→Heat insulation storage tank→Syrup & beverage pump→Semi-auto CIP system→Pipes and valves→Control cabinet

4. RCGF series rinsing filling capping 3in1 machine

Juice Rinsing Machine:

-Rotative rinsing turret one treatment, fixed nozzles, with grippers.

-The grippers take the bottles from the inlet star-wheel while they are still driven by the star-wheel, thus guaranteeing a safe grip.

-After the gripping, the bottle is turned upside down and cantred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Juice Filling machine:

-The star-wheels drive the bottles always "by the neck" through the rinsing, filling and capping steps. For the various types of bottle, it is easy to adjust the structure for the operator by our specialized design.

-Product bowl is to reduce the loss of heat.

-If the temperature is low than the setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank and return to UHT again to sterilize with pump.

Juice Capping machine:

Juice pasteurization system:

Packing system:

Labeling machine→Code Printer→Package machine→Pipes and fittings spare part

Technical parameters:

Model | CGFR8-8-3 | CGFR12126 | CGFR18186 | CGFR24248 |

Number of washing, filling and capping heads | 8-8-3 | 12-12-6 | 18-18-6 | 24-24-8 |

Production capacity(500ml)(B/H) | 2000BPH | 4000 | 7000-8000 | 10000-12000 |

Suitable bottle specification(mm) | volume=330-2000ml | φ=50-110 H=150~340mm volume=330-2500ml | ||

Washing pressure(kg/cm 2 ) | 2-3 | |||

Motor power(kw) | Main motor1.9kw | Main motor3.5kw | Main motor4.0kw | Main motor4.8kw |

Overall dimensions (mm) | 1900*1420*2000 | 2450*1800*2400 | 2650*1900*2400 | 2900*2100*2400 |

Weight (kg) | 1500 | 2500 | 3500 | 4500 |

Model | CGFR323210 | CGFR404012 | CGFR505015 | CGFR606015 |

Number of washing, filling and capping heads | 32-32-10 | 40-40-12 | 50-50-15 | 60-60-15 |

Production capacity(500ml) (B/H) | 12000-15000 | 15000-18000 | 20000-22000 | 22000-25000 |

Suitable bottle specification(mm) | φ=50-110 H=150~340mm Volume=330-2500ml | |||

Washing pressure(kg/cm 2 ) | 2-3 | |||

Motor power(kw) | Main motor7.6kw | Main motor8.3kw | Main motor 9.6kw | Main motor 15Kw |

Overall dimensions (mm) | 4100*2000*2400 | 4550*2650*2400 | 5450*3210*2400 | 5500*3510*2400 |

Weight (kg) | 6500 | 8500 | 9800 | 12000 |