cheap shrink wrap machine one-stop service

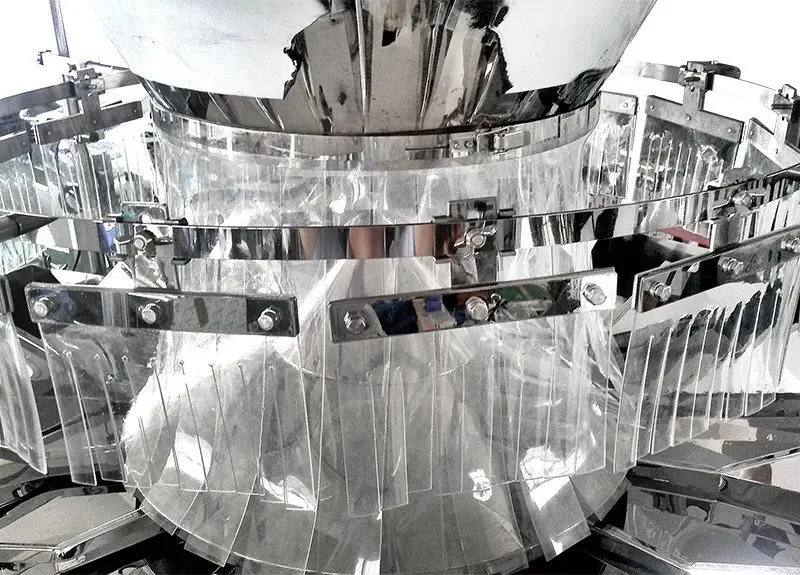

1. There are many important parameters being considered in Kenwei weighing hopper scales design. They are strength, stiffness or rigidity, wear resistance, lubrication, ease of assembly, etc. Kenwei packaging machine is of high accuracy, which helps customers save materials

2. Kenwei has also developed a friendly relationship with the delivery which can also guarantee the fast delivery time. Kenwei packaging machine is manufactured based on industry standards

3. The product features an ergonomic design. The forefoot part is designed with softness and comfort, the arch part with enough support, and the rear part with excellent cushioning. Operation of Kenwei packaging machine is safe and reliable

4. The product is cruelty-free. The contained ingredients have not been tested on animals including acute toxicity testing, eye, and skin irritation testing. Kenwei packaging machine is environmental-friendly

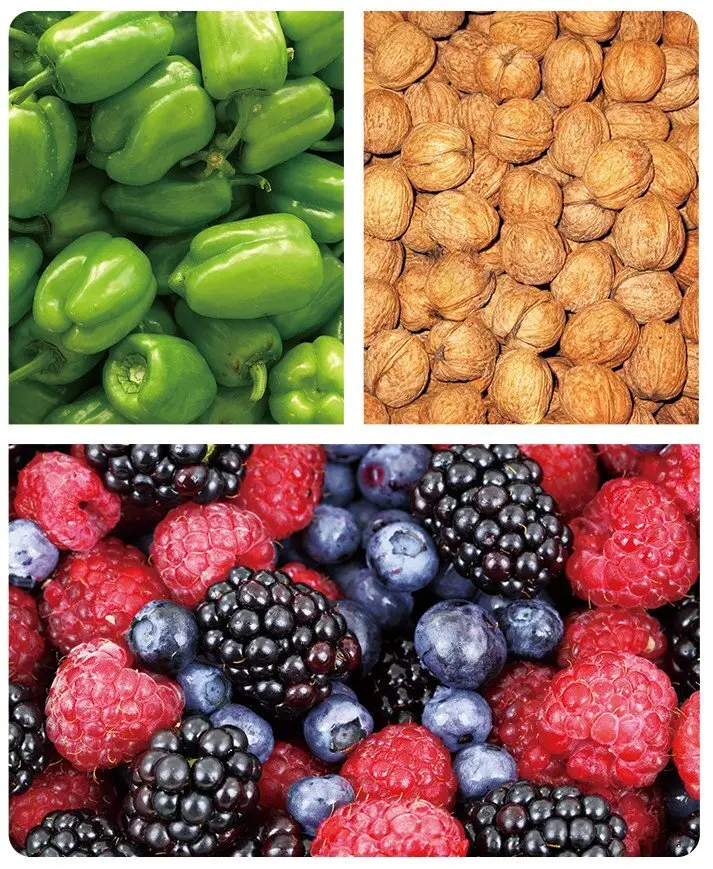

Feeding control multihead weigher is suitable for weighing green pepper, fruit, jelly, and other large bulk materials with less grain count.

The maximum weighing speed of 14 head feeding control multihead weigher is 60 bales/minute, with high weighing accuracy.

Product Features

Product Characteristic

2. Vibration time is automatically adjusted to make sure a good feeding process and improve the combination possibility.

4. Wide V shape feeder pan with an independent photo sensor on its top, feeding process can be more uniform.

6. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time.

Technical Specification

Model | JW-A14 | JW-A10 |

Identify Code | A14-1-8 | A14-1-8 |

Weighing Range | 10-1500g | 10-1000g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 60P/M | 30P/M |

Hopper Volume | 1.6L/2.5L | |

Control Panel | 7” Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1500W/ 50/60Hz //12A | 220V/1000W/ 50/60Hz //10A |

Packing Dimension(mm) | 1700(L)X1110(W)X1265(H) | 1620(L)X1100(W)X1110(H) |

Gross Weight | 490kg | 380kg |

Applications

It is suitable for counting project, such as pepper, fruit, jelly, small packs, tomato, potato, onion, large-shell nuts, etc.

Company Features

1. Our factory has imported a range of advanced production facilities and lines. Owing to these hi-tech facilities and lines, we are capable of conducting smooth business operations.

2. We have drawn up a series of major challenges - going beyond zero environmental impact to deliver positive environmental benefits.