best-selling packing machine price exclusive deal

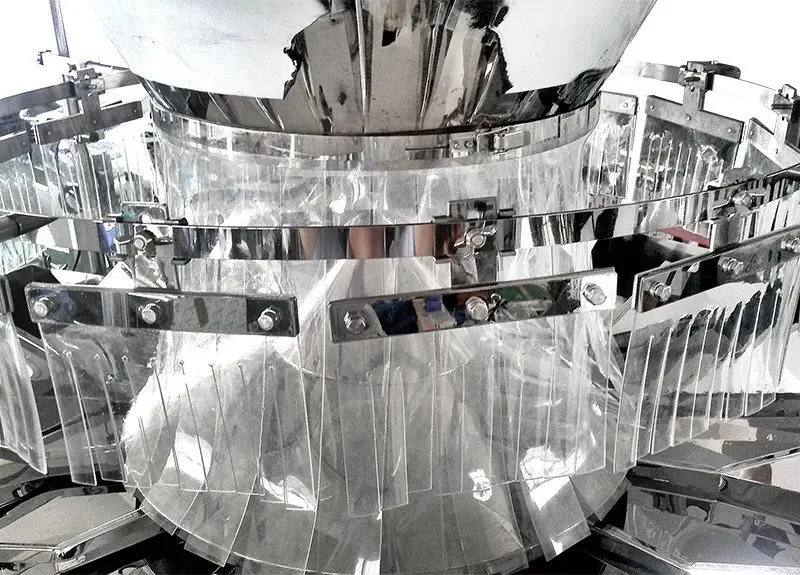

1. The design of Kenwei peanut packaging equipment is of professionalism. It is carried out considering many factors such as mechanical structure, spindles, control system, and part tolerances. High precision molds and excellent components are adopted in Kenwei packaging machine

2. At this point, Guangdong Kenwei Intellectualized Machinery Co.,LTD. has established a huge friendly and mutually beneficial marketing network throughout the world. Each Kenwei packaging machine runs stably

3. The product is unbeatable in terms of performance, longevity, and practicality. Kenwei packaging machine is easy to clean

4. The implementation of the quality control system ensures the product to be defect-free. Maintenance is easy in Kenwei packaging machine

5. Compared with other products, this product has the advantages of long service life, stable performance and good usability. Kenwei packaging machine helps save costs and improve production efficiency

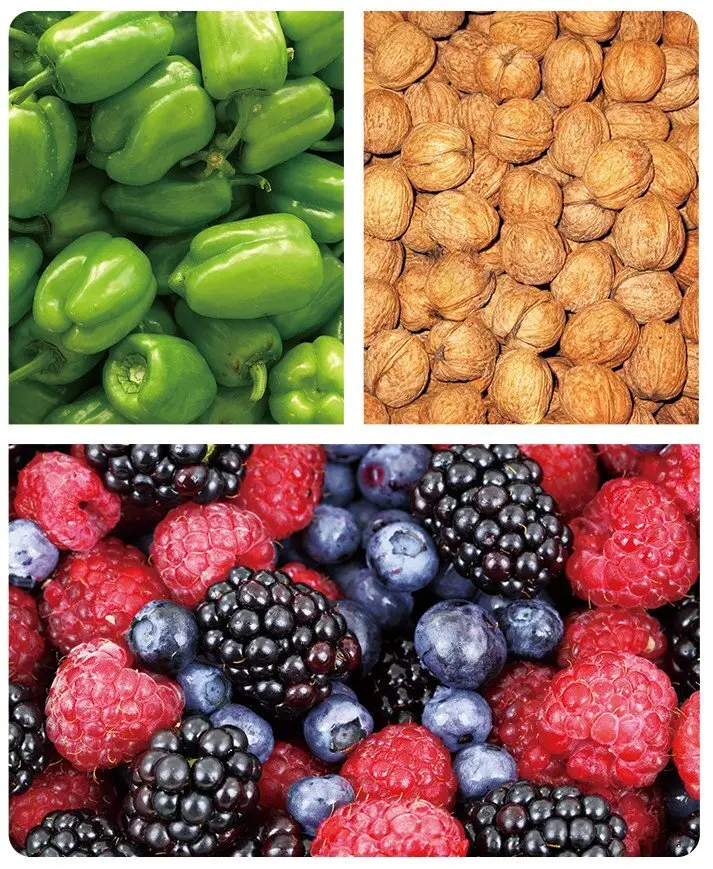

Feeding control multihead weigher is suitable for weighing green pepper, fruit, jelly, and other large bulk materials with less grain count.

The maximum weighing speed of 14 head feeding control multihead weigher is 60 bales/minute, with high weighing accuracy.

Product Features

Product Characteristic

2. Vibration time is automatically adjusted to make sure a good feeding process and improve the combination possibility.

4. Wide V shape feeder pan with an independent photo sensor on its top, feeding process can be more uniform.

6. The whole cast aluminum thickening machine case enhanced the strength of the machine, and shorten sample stable time.

Technical Specification

Model | JW-A14 | JW-A10 |

Identify Code | A14-1-8 | A14-1-8 |

Weighing Range | 10-1500g | 10-1000g |

Accuracy | X(0.5) | X(0.5) |

Max Speed | 60P/M | 30P/M |

Hopper Volume | 1.6L/2.5L | |

Control Panel | 7” Touch Screen | |

Options | Dimple Plate/Timing Hopper/Printer/Reject Device | |

Driving System | Step Motor | |

Power Requirement | 220V/1500W/ 50/60Hz //12A | 220V/1000W/ 50/60Hz //10A |

Packing Dimension(mm) | 1700(L)X1110(W)X1265(H) | 1620(L)X1100(W)X1110(H) |

Gross Weight | 490kg | 380kg |

Applications

It is suitable for counting project, such as pepper, fruit, jelly, small packs, tomato, potato, onion, large-shell nuts, etc.

Company Features

1. We have employed a professional R&D team. Their development know-how enables us to turn our customers’ ideas into high quality and differentiated finished products.

2. We create sustainable growth. We put efforts on how to use materials, energy, land, water, etc. to ensure that we consume natural resources at a sustainable rate.